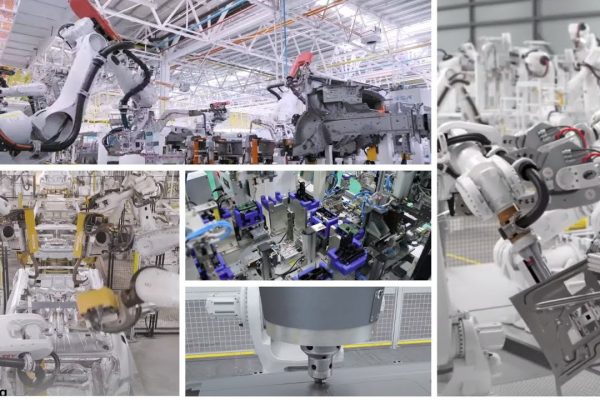

In the era of industry 4.0, automation is no longer an option but has become an inevitable trend. For mechanical factories, steel structures, automobiles and motorbikes, arc welding processes requiring high precision and productivity are being prioritized for automation by welding robots.

ETEK introduces the OmniVance™ FlexArc® automatic arc welding station solution, an intelligent welding robot application that completely replaces manual operations while:

| Parameter | Value |

| Size | 4335 x 4066 x 3350 mm |

| Number of robots | 1-2 |

| Turntable load | 1,000 kg |

| PLC control | B&R or Siemens |

FlexArc® soldering stations are suitable for many industries such as:

With experience in implementing hundreds of automation projects nationwide, ETEK is ready to accompany businesses on the journey of digital transformation and improving production capacity.

Our Assembly Solution is designed to enhance production efficiency, accuracy, and output while minimizing human intervention. By integrating advanced robotics, automated conveyance, and vision-guided technology, the system ensures precision in…

The surface treatment industry, also known as surface processing, is a diverse and important industrial field that involves creating surfaces with different properties to meet the requirements of various applications.…

The case packer machine is a modern solution designed to optimized the automatic packaging process for bagged products. With its quick, precise and flexible operation, the machine not only increases…

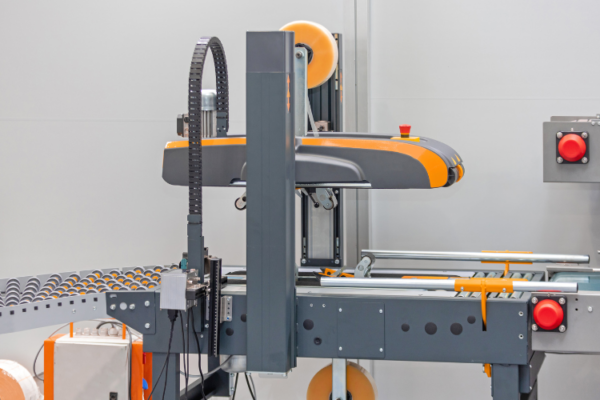

In modern production processes, ensuring that cartons are securely, aesthetically, and efficiently sealed is a critical factor in improving product quality and optimizing packaging lines. The case sealer (carton sealing…