In today’s increasingly competitive environment, manufacturing and logistics companies are facing numerous challenges in warehouse management:

Warehouses are full but still short of space: Inventory continues to grow, but storage areas cannot be expanded further.

Manual management: Relying on paperwork or Excel spreadsheets consumes time and often leads to errors.

Inaccurate inventory control: Data discrepancies between records and actual stock affect production and delivery planning.

Rising labor and operating costs: More workers are needed for handling tasks, yet productivity does not improve accordingly.

This is the time for businesses to adopt Kardex Smart Warehouse Solutions – one of the world’s leading automated storage and retrieval systems.

The Kardex Smart Warehouse is not just a storage device; it’s a comprehensive solution that helps businesses optimize warehouse operations.

The Vertical Lift Module (VLM) design maximizes the use of vertical height in the facility.

Saves up to 85% of floor space compared to traditional warehouses.

Allows businesses to free up space for production expansion or other functional areas.

The system automatically delivers trays to the operator’s access point.

Reduces walking and searching time for staff.

Greatly increases order processing speed to meet continuous production demands.

Integrated Warehouse Management Software (WMS) synchronizes with ERP systems.

Achieves near-perfect inventory accuracy.

Minimizes losses and human errors in receiving, picking, and stock-taking processes.

Less reliance on manual labor reduces staffing expenses.

Automation streamlines multiple operational steps, saving long-term costs.

Increases efficiency without expanding warehouse size or hiring additional workers.

Businesses can experience the Kardex Smart Warehouse in action at FBC ASEAN 2025 – a premier event for supply chain and industrial connection.

Venue: VNEC – Dong Anh, Hanoi

Date: September 17–19, 2025

Booth: R97 (ETEK)

At the booth, visitors can:

Observe live demonstrations of Kardex Smart Warehouse operations.

Receive personalized consultation from ETEK experts on suitable solutions for different business types.

Experience how the system helps boost productivity, reduce costs, and enhance competitiveness.

With years of experience in deploying automated warehouse systems and smart industrial equipment, ETEK is committed to delivering:

World-class solutions tailored to Vietnamese market needs.

A highly skilled technical team that supports clients from consultation to installation and maintenance.

Dedicated after-sales service ensuring stable, long-term, and efficient system operation.

Introduction to Kardex Smart Warehouse The application of advanced technology in warehouse management has become an inevitable trend to enhance efficiency and reduce costs. Therefore, Kardex—with its long-standing history and…

What is Sealing? Sealing is the process of creating a protective layer or barrier to prevent the intrusion or leakage of liquids, gases, dust, or other contaminants between surfaces or…

In the context of the strong explosion of Industry 4.0, the metal casting industry - one of the fundamental industries - is constantly innovating to keep up with the trend.…

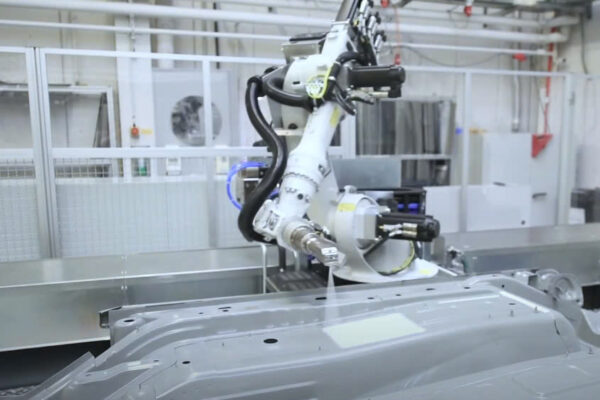

Welding robots are widely used in manufacturing plants of various large and small scales. With a large investment capital, high requirements but bringing practical benefits to production activities and the…