In the industrial kitchen equipment manufacturing industry, the quality of the weld not only determines the durability and safety but also directly affects the aesthetics of the product. In particular, with stainless steel parts in the form of tubes, round shafts or complex structures, creating seamless, pressure-resistant and beautiful welds is always a big challenge for manual welders.

To solve this problem, the deployed automatic welding Cobot solution brings outstanding efficiency, helping businesses increase productivity, reduce errors and optimize production costs.

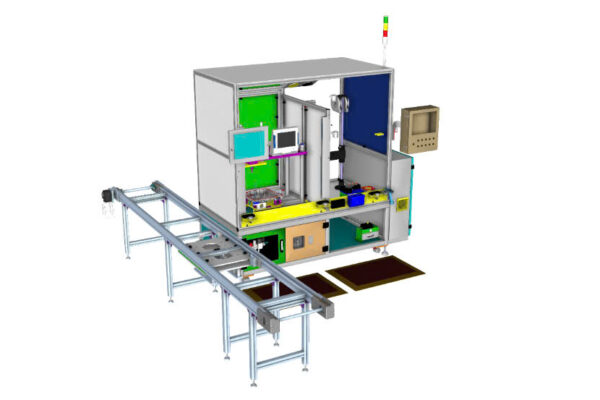

The ABB GoFa™ CRB 15000 collaborative robot application system combined with the Kemppi Master M 358 welding machine and GXe-C welding torch, offers many superior features:

Thanks to that, the cobot can automatically compensate for detail deviations, without the need for complex fixtures, ensuring precise and uniform circular welds.

When applying automatic Cobot welding solutions to production, businesses will receive many practical values:

The Cobot welding automation solution not only helps improve productivity and quality, but also opens up new directions for businesses in the industrial kitchen equipment manufacturing industry. With the combination of the ABB GoFa™ CRB 15000 robot and the Kemppi Master M 358 welding machine, ETEK provides a comprehensive, flexible and efficient solution for all modern production processes.

Contact ETEK now for detailed advice on the optimal automatic welding robot solution for your business.

In industrial production lines, every assembly step plays a vital role in ensuring the quality of the final product. One of the key steps is pin pressing, which helps secure…

You may be familiar with traditional warehouses that offer spacious, open spaces for receiving and storing goods. However, with the development of technology, smart warehouses were born to help perform…

Are you looking for an automated confectionery packaging solution where pick-and-place robots operate with precision, box sealing systems work efficiently and the entire process runs smoothly with a high level…

In the modern automotive industry, automatic robots are transforming the coating process by ensuring consistent and highly precise paint application. This advanced technology is particularly vital for chassis components, where…