The Pick to Light system integrated into automotive assembly plants is an efficient solution that helps workers quickly and accurately select components, reducing errors and improving productivity.

The Pick to Light (PTL) system is a technology solution that uses lights or illuminated devices to locate goods, enabling operators to quickly and accurately identify and retrieve components. These lighting devices are typically installed on racks or shelves at fixed picking locations, displaying the required quantity through an LED screen.

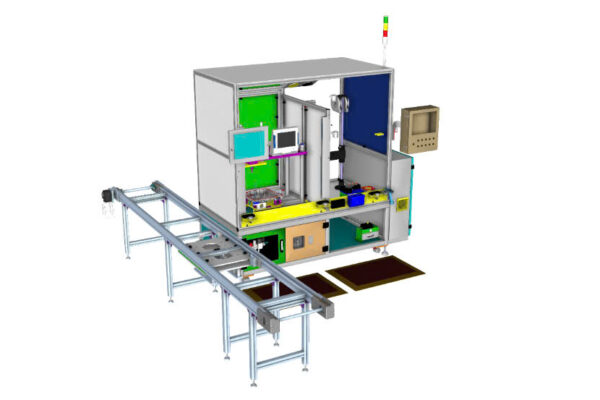

In the automotive manufacturing sector, manufacturers integrate the Pick to Light system directly into the assembly process. This system helps workers retrieve components quickly and accurately, ensuring a smooth and efficient workflow.

At the start of the process, the management software sends order information to the PTL system. The LED lights at the required component locations illuminate, displaying the specific quantity and guiding workers in picking the correct items. Once completed, workers confirm their actions, and the system automatically updates the status, proceeding to the next task, ensuring a continuous and efficient workflow.

Contact ETEK today for detailed consultation!

The electric vehicle revolution demands cutting-edge battery manufacturing solutions that deliver exceptional performance, safety, and reliability. ETEK Automation provides comprehensive electric vehicle battery assembly line systems that integrate advanced automation…

In recent years, Vietnam's automotive industry has witnessed remarkable progress, largely due to the adoption of modern technologies in automotive assembly systems. This advancement has not only improved product quality…

In industrial production lines, every assembly step plays a vital role in ensuring the quality of the final product. One of the key steps is pin pressing, which helps secure…

In modern automotive manufacturing, the painting process not only enhances aesthetics but also plays a critical role in determining product durability and overall value. ETEK provides a total automotive body…