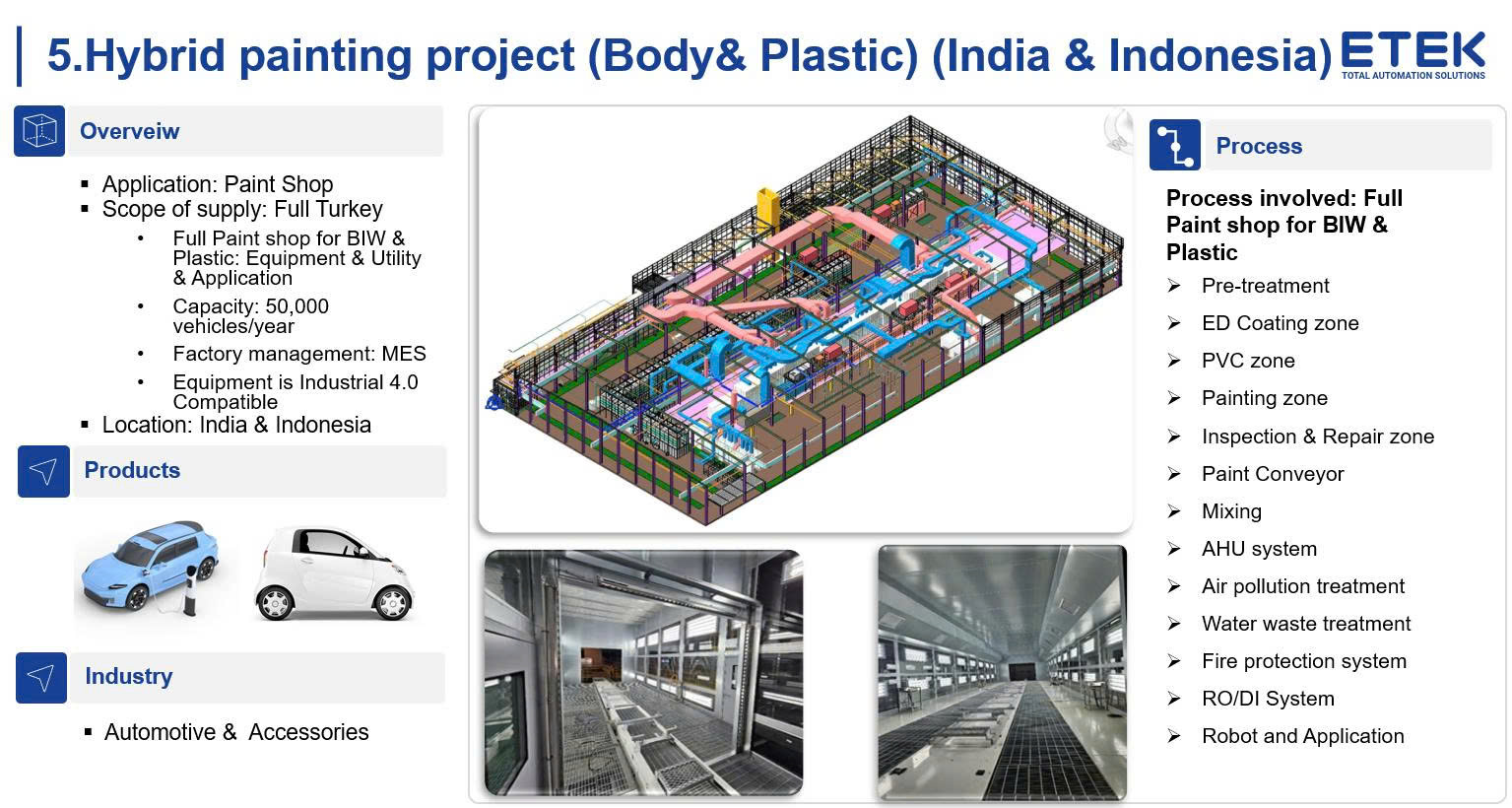

In modern automotive manufacturing, the painting process not only enhances aesthetics but also plays a critical role in determining product durability and overall value. ETEK provides a total automotive body painting line that is fully integrated and synchronously designed to meet the requirements of export-oriented automotive production and international quality standards. The solution is suitable for both vehicle bodies and plastic components, ensuring consistent coating quality and efficient operation.

The system is currently operating stably, applying advanced technologies with a capacity of up to 50,000 units per year, ready to support large-scale production.

The painting line is designed as a closed-loop system with specialized functional zones to ensure flawless surface quality:

Our painting solution adapts to various industries requiring high-quality and consistent surface finishes:

Contact ETEK for more detailed consultation

Let ETEK partner with you from assessment – design – manufacturing – installation – technology transfer.

Address: 189 Phan Trong Tue Street, Thanh Liet Ward, Thanh Tri District, Hanoi, Vietnam

Hotline: 0965800166

Email: info@etek.com.vn

Website: https://etekautomation.com.vn

Operated on the “goods-to-person” principle, the VLM increases productivity by delivering items directly to the operator.These systems feature a flexible modular design, allowing future adjustments to meet your business needs.…

The Pick to Light system integrated into automotive assembly plants is an efficient solution that helps workers quickly and accurately select components, reducing errors and improving productivity. Understanding the Pick…

In the era of industry 4.0, motorbike and automobile manufacturing enterprises increasingly focus on automation, improving productivity and stabilizing product quality. Especially, with products such as motorbike frames - the…

In the industrial kitchen equipment manufacturing industry, the quality of the weld not only determines the durability and safety but also directly affects the aesthetics of the product. In particular,…