In the context of increasingly fierce competition, optimizing warehouse operations is a key factor to help businesses improve efficiency, reduce costs and serve customers faster. One of the advanced technology solutions being pioneered by businesses is ASRS (Automated Storage and Retrieval System ) .

Not only does it deliver superior performance, the ASRS system also completely changes the way traditional warehouses operate. Below are four outstanding benefits that ASRS brings, proving why it is the top choice for upgrading smart warehouses in the era of industry 4.0.

One of the biggest differences of the ASRS system is the Goods to Person (G2P) model – bringing goods to people, instead of people finding goods. This helps:

Instead of relying entirely on human power, the G2P system in ASRS helps create a more modern, friendly and efficient working environment.

.png)

Increased productivity is the number one reason businesses invest in ASRS. By fully automating the storage and retrieval process, businesses can:

The stability, accuracy and high speed of ASRS help businesses save operating costs and improve customer service capacity.

%20(1).png)

In big cities or industrial zones, the cost of renting space is increasing. Therefore, optimizing warehouse space becomes an urgent requirement. ASRS solves this problem with smart storage solutions:

Thanks to that, businesses can reduce warehouse rental costs , expand storage capacity without expanding floor space, very suitable for growing businesses or businesses with space limitations.

%20(2).png)

One of the biggest challenges in warehouse operations is errors in storage and delivery , causing loss, delayed orders, and affecting brand reputation. The ASRS system completely solves this problem thanks to technology:

The result is:

With ASRS, businesses not only optimize operations but also build a comprehensive , transparent and modern warehouse control system .

%20(3)(1).png)

In the trend of digital transformation in the logistics and manufacturing industry , the ASRS system is becoming a strategic choice to help businesses:

Whether you are an e-commerce business, a manufacturing plant or a distribution center – ASRS is the breakthrough to make your warehouse smarter, more agile and more sustainable .

If you are looking for an efficient, flexible and reliable automated warehouse solution , explore the ASRS product range from Kardex – the world leader in storage automation.

What is automation in the metal industry? The metal industry is one of the most versatile industries and is therefore identified as a priority for robot-based automation solutions. This sector…

In the era of industry 4.0, automation is no longer an option but has become an inevitable trend. For mechanical factories, steel structures, automobiles and motorbikes, arc welding processes requiring…

Smart warehouses is a storage system that utilizes advanced technologies such as automation, the Internet of Things (IoT), Artificial Intelligence (AI), and Big Data to efficiently and accurately manage storage,…

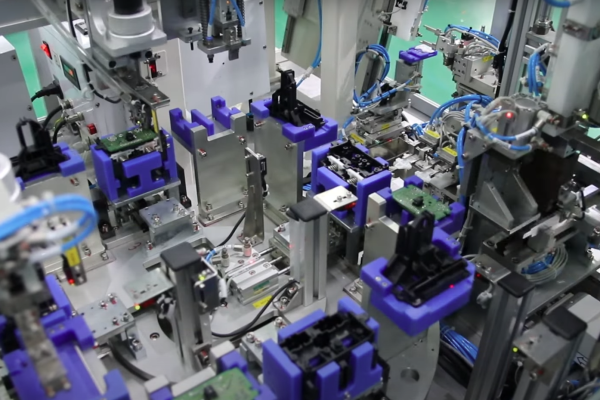

What is automation in the electrical and electronics industry? Automation in the electrical and electronics industry is essential in improving production efficiency, reducing labor costs, and ensuring safety in manufacturing…