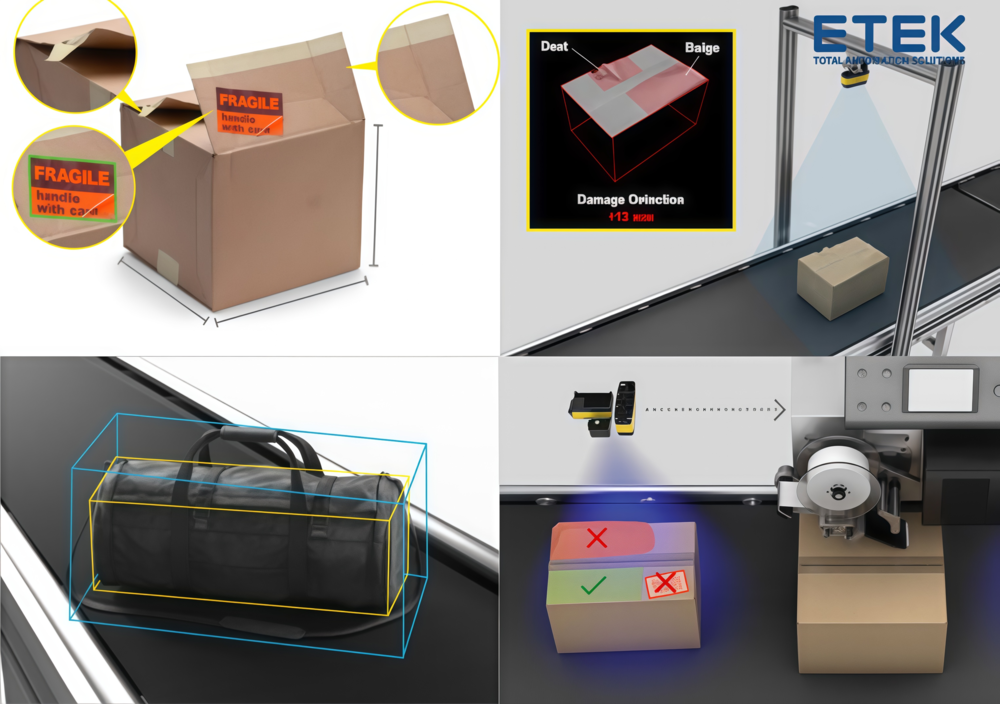

The 3D-A1000 dimensioning system is a compact industrial smart camera capable of capturing moving objects in both 2D and 3D. It is equipped with powerful vision tools that enable automation of tasks such as container fill measurement, damage detection, feature recognition, and many other applications.

The solution delivers fast, stable results and is easy to deploy, making it suitable for logistics operations of any scale. It helps to:

Unlike conventional methods, the 3D-A1000 uses patented 3D structured light technology that freezes motion with a single capture. This enables the generation of highly accurate 3D point cloud data without complex calibration or encoder integration. Embedded processing allows Cognex vision tools to run simultaneously for both 2D and 3D inspections.

The 3D-A1000 Multi-Head system captures data from multiple viewing angles, expanding coverage and improving dimensioning accuracy. Its flexible configuration and easy deployment support applications involving narrow gaps and high-speed conveyor systems.

The 3D-A1000 is factory calibrated and ready for system integration immediately after installation. Compared to traditional solutions that require 3–6 hours of setup by skilled engineers, the 3D-A1000 can be installed in under 15 minutes using an intuitive setup wizard:

Step 1: Quick connection without complex software installation

Step 2: Installation simulation wizard assists with optimal mounting and alignment

Step 3: The system is ready to operate and automatically certifies performance

Step 4: Continuous statistical feedback supports process analysis and optimization

Through the 3D-A1000 component inspection solution, ETEK delivers an optimized industrial vision system for logistics, enabling businesses to improve measurement accuracy, standardize processes, and maximize operational efficiency without manual intervention.

The system integrates powerful vision tools to automate a wide range of tasks, including:

Contact ETEK for more detailed consultation

Let ETEK partner with you from assessment – design – manufacturing – installation – technology transfer.

Address: 189 Phan Trong Tue Street, Thanh Liet Ward, Thanh Tri District, Hanoi, Vietnam

Hotline: 0965800166

Email: info@etek.com.vn

Website: https://etekautomation.com.vn

The automatic screwdriving cobot solution for automated assembly lines enables safe human–robot collaboration without the need for safety fences, ensuring high precision, stable productivity, continuous operation, and ease of use.…

Modern laser engraving machines have become indispensable tools in various manufacturing and processing industries due to their ability to cut, engrave, and mark with exceptional precision and speed. This technology…

In the context of the booming Industry 4.0, metal stamping automation is no longer an option but a mandatory trend if businesses want to increase productivity, ensure quality and minimize labor risks. Industrial…

In the modern automotive industry, automatic robots are transforming the coating process by ensuring consistent and highly precise paint application. This advanced technology is particularly vital for chassis components, where…