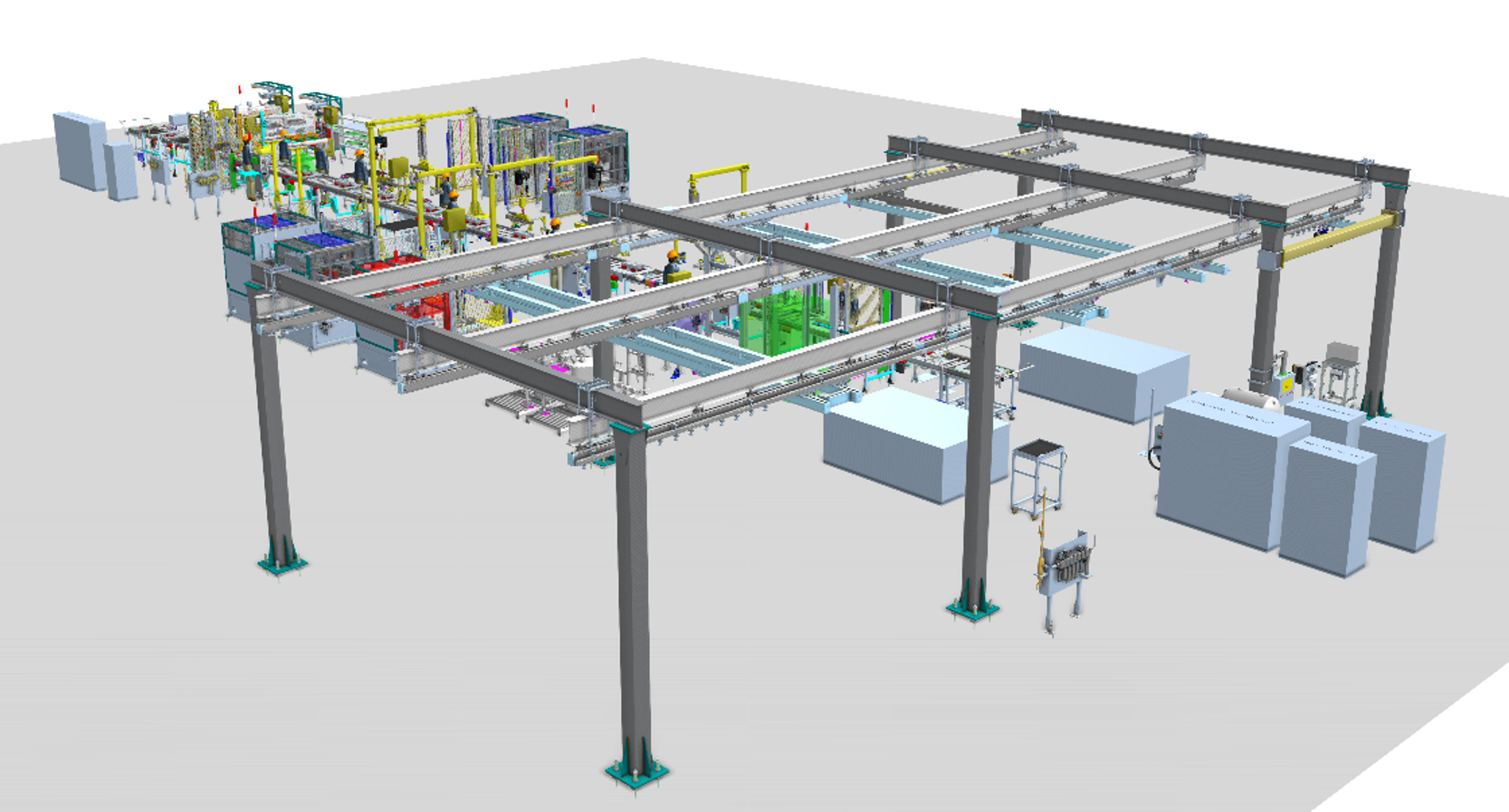

The electric vehicle revolution demands cutting-edge battery manufacturing solutions that deliver exceptional performance, safety, and reliability. ETEK Automation provides comprehensive electric vehicle battery assembly line systems that integrate advanced automation technology to meet the stringent requirements of the rapidly expanding EV industry.

Electric Vehicle Battery Packs for:

Our assembly line features a comprehensive 13-step precision process designed for maximum safety and performance:

ETEK Automation specializes in high-precision battery manufacturing with advanced safety protocols and quality assurance systems. Our solutions integrate cutting-edge welding technology, automated testing equipment, and intelligent monitoring systems to ensure reliable, high-performance battery production that meets automotive industry standards.

Transform your battery manufacturing capabilities with ETEK’s state-of-the-art automation solutions. Our expert team provides complete support from design consultation through implementation and maintenance.

Refer to ETEK’s completed projects HERE

Contact ETEK Automation Today:

Address: 189 Phan Trong Tue Street, Thanh Liet Ward, Thanh Tri District, Hanoi, Vietnam

Phone: 0965 800 166

Email: info@etek.com.vn

Website: https://etekautomation.com.vn

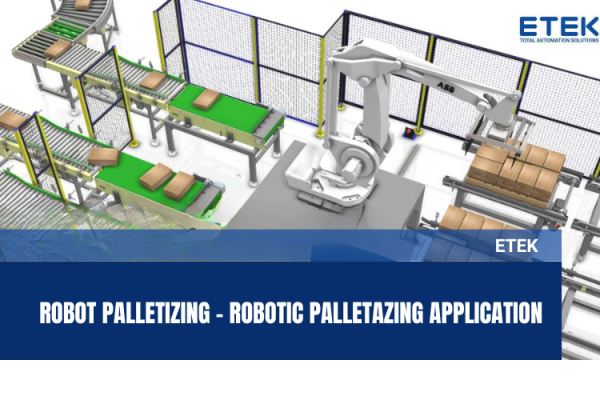

Palletizing robots are one of the industrial robot applications that offer many benefits and are highly appreciated in the manufacturing plant. They are in charge of loading and unloading goods,…

A thermal transfer printer ( also known as a TTO - Thermal Transfer Overprinting machine) is a device that uses thermal transfer technology to print on packaging surfaces or other…

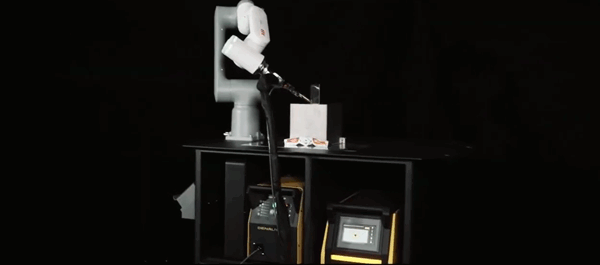

The automatic screwdriving cobot solution for automated assembly lines enables safe human–robot collaboration without the need for safety fences, ensuring high precision, stable productivity, continuous operation, and ease of use.…

The application of automated laser welding combined with 6-axis robots is becoming a mainstream trend in modern manufacturing plants. This technology provides optimal solutions for precision welding requirements on many different types of materials.…