In the automotive manufacturing industry, the quality of the paint layer not only determines the aesthetic appeal but also directly affects the durability of the product. The application of painting robots helps businesses achieve high precision, maintain strict quality control, and optimize production costs. This automated system is gradually replacing traditional painting methods, offering outstanding benefits in productivity, material savings, and workplace safety.

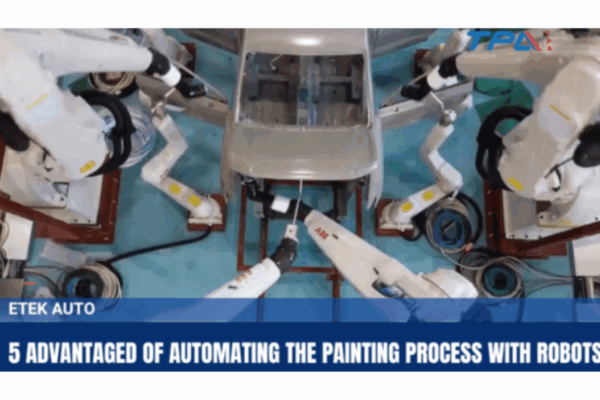

Painting robots operate based on precise programming, ensuring perfect control over spray patterns, paint thickness, and application techniques. As a result, the paint layer is evenly coated, completely eliminating common defects such as streaks, spots, or air bubbles—issues often encountered in manual painting. Additionally, reducing the need for rework not only saves materials but also optimizes production costs.

With a spraying speed of up to 1000mm/s, painting robots work significantly faster than traditional methods. The fully automated system operates continuously without breaks, shortening production time and improving efficiency.

Thanks to optimized spraying technology, painting robots can reduce paint loss by up to 30% compared to manual methods. This not only saves materials but also minimizes solvent evaporation, reducing negative environmental impacts. Additionally, the efficient operation of the system lowers energy consumption, further optimizing production costs.

Automotive paint contains various hazardous chemicals that can affect workers’ health when exposed for prolonged periods. Using painting robots eliminates this risk, reducing exposure to toxic fumes and minimizing occupational health hazards. Furthermore, robots help lower the risk of fire and explosions in environments with flammable chemicals.

One of the standout advantages of painting robots is their easy reprogramming capability, allowing businesses to quickly adapt to new vehicle models. The system can also be integrated into existing production lines without requiring major factory modifications. As production demands increase, businesses can scale up operations without significant challenges.

Using painting robots reduces the number of workers required in the painting area, leading to savings on wages and training costs. Moreover, automated systems have high durability, reducing maintenance needs and extending equipment lifespan, helping businesses optimize long-term operational expenses.

The painting robot follows a pre-programmed path, ensuring precise paint application on every detail of the vehicle. With smart sensors, the system can automatically adjust paint flow and spraying speed, ensuring an even coating across all surfaces.

After painting, the inspection system evaluates adhesion, smoothness, and color consistency. These parameters are compared against set quality standards to ensure uniformity across all products.

At the end of each shift, the system is flushed to remove residual paint inside, preventing nozzle clogging. This process helps maintain stable spraying quality and prolongs the lifespan of the equipment.

Regular maintenance not only ensures smooth robot operation but also minimizes potential production line failures, maintaining optimal performance and reducing long-term repair costs.

With clear advantages in quality, productivity, and cost efficiency, painting robots have become an essential solution in modern automotive manufacturing. Investing in this technology not only optimizes production processes but also contributes to creating a safe, professional, and sustainable working environment.

To learn more about painting robot solutions and receive tailored consultation for your business, contact ETEK today for detailed support!

[embed]https://www.youtube.com/watch?v=-Vy6z_l6GcQ[/embed] Application of ABB Robot for automatic car painting Many businesses are hesitant to start considering the application of automation to the production line due to the large initial investment…

In the context of industry 4.0, automating processes has become an inevitable trend for businesses. Among the prominent solutions, palletizer robots are considered advanced technology that helps optimize product packaging…

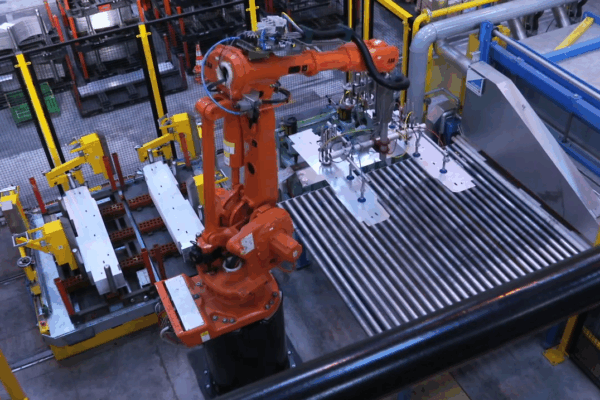

In the context of the booming Industry 4.0, metal stamping automation is no longer an option but a mandatory trend if businesses want to increase productivity, ensure quality and minimize labor risks. Industrial…

Welding robots are widely used in manufacturing plants of various large and small scales. With a large investment capital, high requirements but bringing practical benefits to production activities and the…