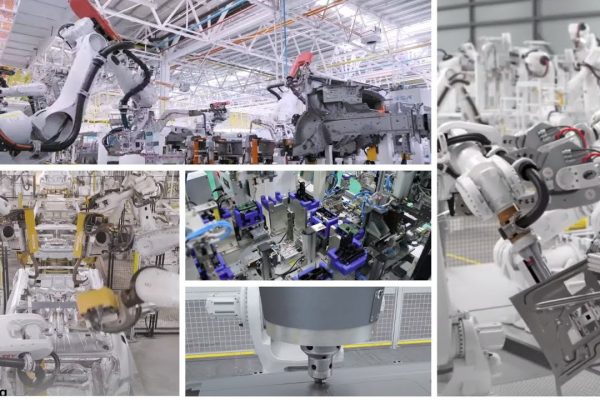

The application of automated laser welding combined with 6-axis robots is becoming a mainstream trend in modern manufacturing plants. This technology provides optimal solutions for precision welding requirements on many different types of materials.

The application includes the following main components:

✔ Ability to work continuously with high stability

✔ Absolute precision on complex welds

✔ Minimizes thermal distortion compared to traditional methods

✔ Can handle many types of materials with different thicknesses

✔ Easy to integrate into existing production lines

The application is especially suitable for:

Contact ETEK for detailed advice

A thermal transfer printer ( also known as a TTO - Thermal Transfer Overprinting machine) is a device that uses thermal transfer technology to print on packaging surfaces or other…

The automatic screwdriving cobot solution for automated assembly lines enables safe human–robot collaboration without the need for safety fences, ensuring high precision, stable productivity, continuous operation, and ease of use.…

In today's competitive electrical and electronics manufacturing landscape, cooling fans are critical components powering computers, industrial equipment, and consumer electronics worldwide. Meeting demanding requirements for consistent quality, high-speed production, and…

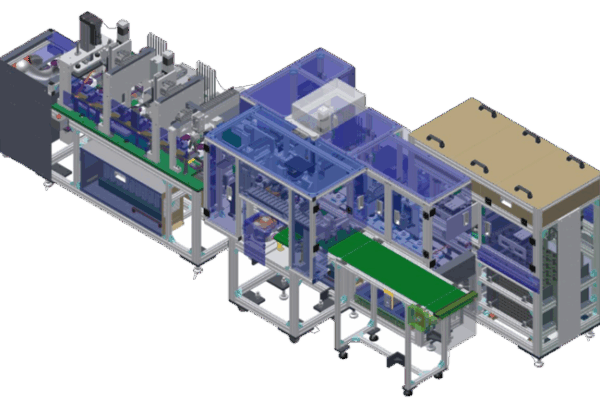

Our Assembly Solution is designed to enhance production efficiency, accuracy, and output while minimizing human intervention. By integrating advanced robotics, automated conveyance, and vision-guided technology, the system ensures precision in…