In the context of the automobile industry increasingly moving towards automation and high quality , the application of car bumper polishing robots has become an inevitable trend to help businesses improve productivity, optimize costs and ensure product aesthetics.

Car bumpers are not only a safety protection part but also play an important role in shaping the style and aesthetic value of the car. However, the traditional manual polishing process often encounters many limitations such as:

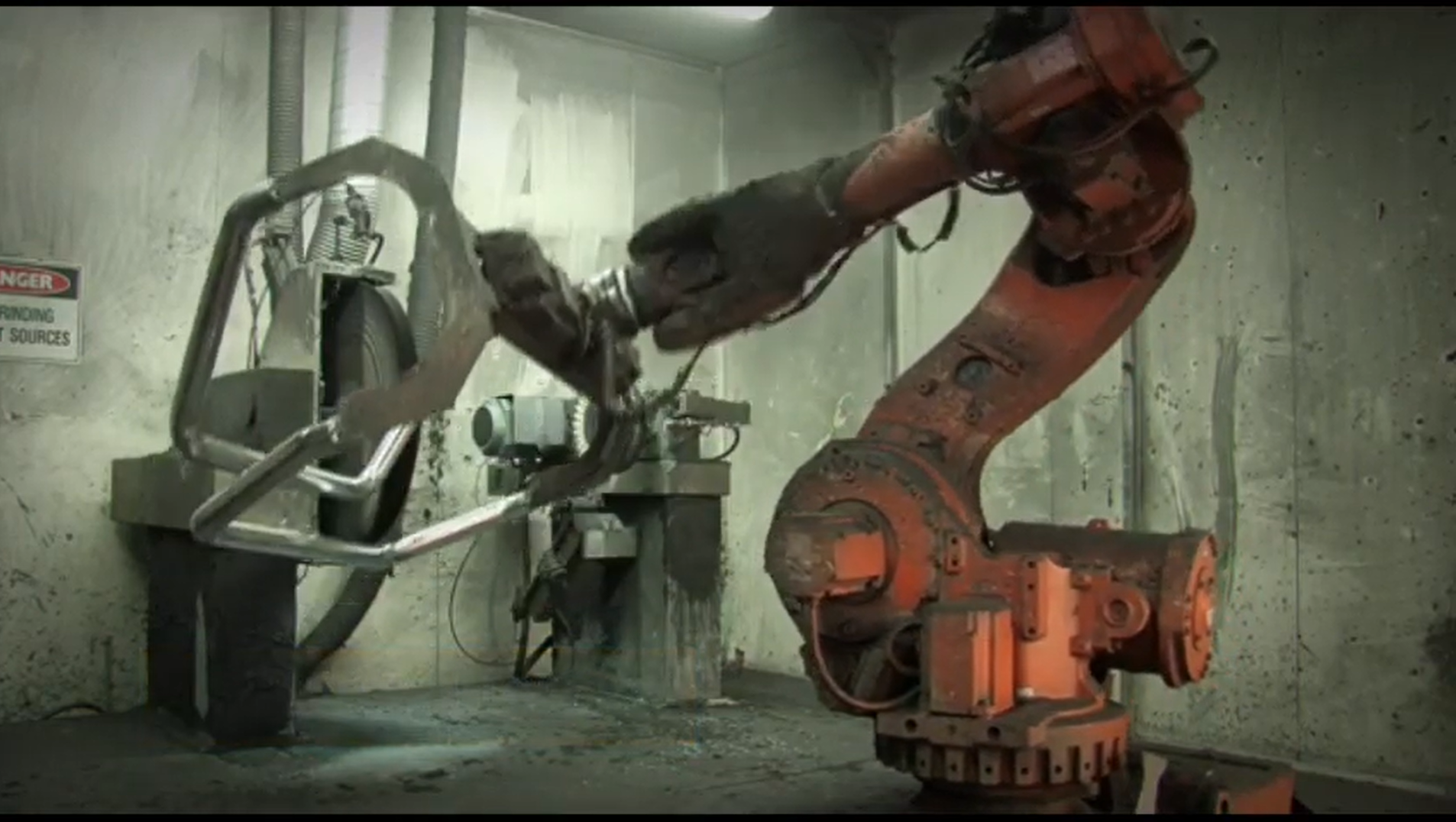

Therefore, the automatic car bumper polishing robot solution was born to thoroughly solve the above problems.

Industrial robots can operate continuously 24/7 with high precision, reducing dependence on manual labor, thereby helping businesses save operating costs and increase production speed.

With the ability to precisely control polishing force and speed, the treated bumper surface becomes smooth and even – meeting the strict quality standards of the automotive industry.

The automation process eliminates the risk of exposure to grinding dust and noise, creating a safer and more friendly working environment.

The system integrates force sensors and monitoring software to monitor the quality of each part in real time – ensuring the product always meets standards.

The flexible clamping mechanism allows the robot to easily handle many different types of bumpers without changing the mechanical structure – suitable for production lines with diverse models.

The automated polishing robot solution includes the following main components:

Investing in a car bumper polishing robot solution not only brings long-term economic efficiency but also enhances the professionalism and modernity of the production line. This is a necessary step for businesses in the automotive industry to catch up with the trend of smart manufacturing and sustainable development in the future.

If your business needs to automate polishing lines or wants to learn more about industrial robot solutions in the automotive industry , please contact us:

Hotline: (+84) 965 800 166

Website: etekautomation.com.vn

Free technical consultation – Field survey – Design customized solutions for each product type

What is automation in the consumer goods industry? The consumer goods manufacturing industry produces everyday life essentials such as detergents, etc. Currently, the development of automation in the consumer goods…

Palletizing is the process of loading products onto pallets on demand. In the final stage of the packaging line, the robot performs the task of bagging, the robot loads the…

Modern laser engraving machines have become indispensable tools in various manufacturing and processing industries due to their ability to cut, engrave, and mark with exceptional precision and speed. This technology…

To maximize the flexibility of ABB's robotic welding cells, the automotive parts manufacturing plant quickly installed 27 FlexArc robots to respond faster to end customer needs while maintaining cost efficiency.…