Our Surface Treatment Solution is designed to enhance the durability, appearance, and functionality of metal and plastic components by applying a range of protective coatings and finishes. This solution automates processes such as polishing, grinding, deburring, and sanding, thereby ensuring that products consistently receive high-quality surface treatments. Moreover, industries such as automotive, aerospace, electronics, and industrial manufacturing widely use the system, where surface quality and protection are critical.

With advanced automation, our surface treatment solution not only ensures precision and efficiency but also provides significant cost savings. Furthermore, it delivers superior surface finishes that enhance corrosion resistance, wear resistance, and overall aesthetics.

Machines Used

- Automated Polishing Systems: These machines smooth and polish surfaces to achieve the desired finish, whether it’s a high-gloss shine or a matte texture.

- Electroplating Systems: Used to apply thin layers of metal coatings (such as zinc, nickel, or chrome) to enhance the appearance and protect metal parts from corrosion.

- Anodizing Equipment: Automated systems for anodizing aluminum components, providing a durable and corrosion-resistant surface finish.

- Powder coating machines evenly apply powder coatings to metal surfaces, then cure them under heat to form a durable and protective layer.

- Surface Cleaning and Preparation Systems: Before applying any surface treatment, our system cleans and prepares the surface to ensure that coatings adhere properly and last longer.

Applications in Industry

Our material surface treatment automation solution can be applied to various product surfaces such as metals, plastics, wood, etc. The applications use robots to replace human operators in performing different tasks such as grinding, sanding, polishing, and deburring. Therefore, it optimizes production efficiency for several industries:

- Automated surface treatment solutions can treat automotive and motorcycle components, such as deburring steering wheels, polishing bodies, and covers.

- Electric/Electronics: Automation of the polishing process for casings and machine bodies. Polishing metal product details, etc.

- Woodworking: Automating the smoothing and sanding processes for wooden products to enhance aesthetics.

- Food Processing: The automation solution can be used to clean and treat the surfaces of food processing equipment, ensuring hygiene and food safety. Polishing and cleaning surfaces that come into contact with food will minimize the risk of contamination.

- Healthcare: In the healthcare industry, surface treatment automation is applied to medical devices such as surgical instruments and assistive equipment. Polishing and cleaning metal surfaces help ensure hygiene and safety standards for users.

With its flexible application across various industries, our surface treatment automation solution boosts production efficiency, reduces costs, and improves product quality.

Benefits

- High-Precision Coating Application: The automated system applies coatings such as paint, powder, or anodized layers evenly across the surface of the component, ensuring a uniform finish.

- Versatility in Surface Treatment: The solution supports a wide variety of surface treatments, including electroplating, anodizing, powder coating, and polishing, catering to the specific needs of different industries.

- Consistent Quality: By automating the surface treatment process, we ensure that every component receives the same level of care and precision, resulting in consistent quality across all products.

- Cost Efficiency: Automation reduces labor costs and material waste, ensuring that surface treatment processes are both efficient and cost-effective.

- Consistency and Quality Control: Automated systems apply coatings uniformly and precisely, ensuring that each product receives the same high level of surface protection.

- Reduced Environmental Impact: Our surface treatment solution optimizes material usage and minimizes waste, making it more environmentally friendly compared to traditional manual processes.

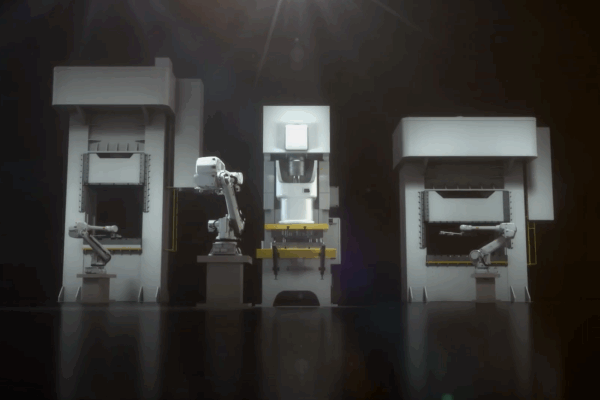

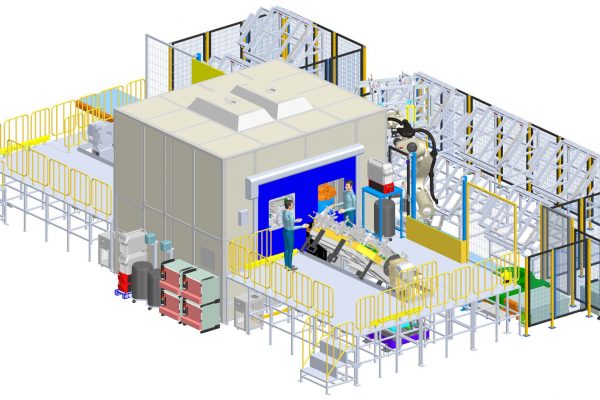

Application of robots for sanding and polishing products

Components

- Robot/Cobot: Programmed to operate according to a predefined program. They perform tasks that replace human operators.

- Tool/Vision: The tool usually mounts on the end of each robot/cobot, directly contacting the product’s surface. Vision includes image sensors that monitor and recognize the surface of the product being worked on.

- Programming Software: This includes the PLC program, which the robot’s operational program uses to complete the task.

- Mounting Structure: This includes mechanical structures for holding the product in place.