Our Stamping Solution provides an efficient, high-speed method for producing stamped components from metal and plastic materials. Using automated stamping machines, robots, sensors, vision systems, conveyors, etc., to meet the requirements for high-precision, mass production. With the ability to handle large volumes of material and produce parts at rapid speeds, our stamping solution significantly improves the efficiency of the manufacturing process while maintaining exceptional quality.

This solution is highly suitable for industries that require mass production of intricate metal or plastic components, such as automotive, electronics, and consumer goods.

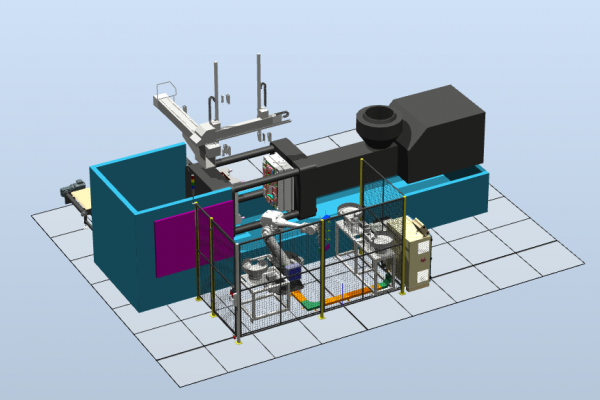

To carry out the assigned stamping tasks, the automated system for stamping applications typically includes:

Our stamping solution is versatile and applied across various industries where mass production and precision are crucial:

The casting industry is a manufacturing sector that creates products by pouring materials in a liquid state into molds to produce items with shapes identical to the mold. This process…

In the era of industry 4.0, automation is no longer an option but has become an inevitable trend. For mechanical factories, steel structures, automobiles and motorbikes, arc welding processes requiring…

The automatic bottle filling machine is an essential device in modern production lines, designed to automate the process of filling liquid products into packaging quickly and efficiently. With advanced technology,…

In modern manufacturing, repetitive tasks such as picking and transferring products between production stages not only consume time but also waste human resources. The High-Speed Pick and Place System emerges…