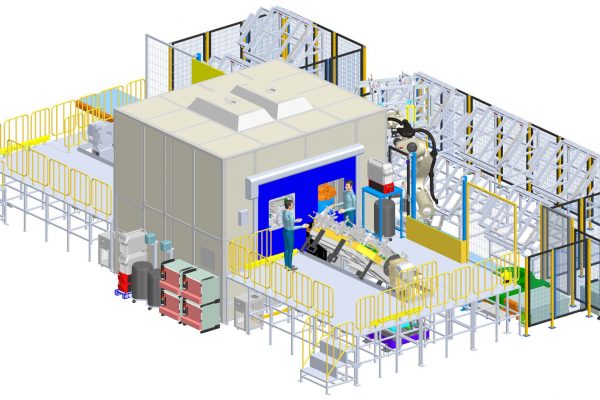

Our Stamping Solution provides an efficient, high-speed method for producing stamped components from metal and plastic materials. Using automated stamping machines, robots, sensors, vision systems, conveyors, etc., to meet the requirements for high-precision, mass production. With the ability to handle large volumes of material and produce parts at rapid speeds, our stamping solution significantly improves the efficiency of the manufacturing process while maintaining exceptional quality.

This solution is highly suitable for industries that require mass production of intricate metal or plastic components, such as automotive, electronics, and consumer goods.

To carry out the assigned stamping tasks, the automated system for stamping applications typically includes:

Our stamping solution is versatile and applied across various industries where mass production and precision are crucial:

Entering the industrial revolution 4.0, many businesses around the world are gradually focusing on investing in the development and production of service (support) robots. Industrial welding robots are one of…

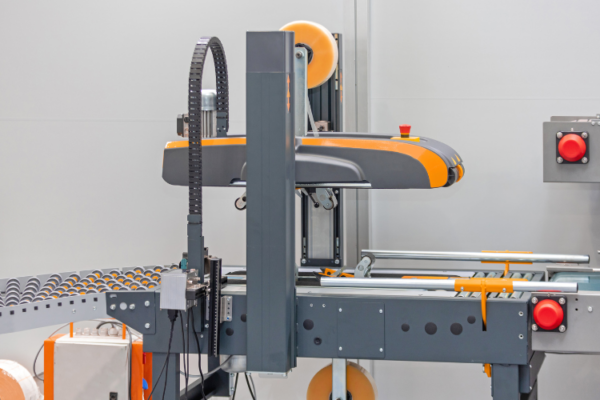

In modern production processes, ensuring that cartons are securely, aesthetically, and efficiently sealed is a critical factor in improving product quality and optimizing packaging lines. The case sealer (carton sealing…

Our Welding Solution offers an advanced, fully automated system for performing a wide range of welding tasks with precision and consistency. This solution is ideal for industries that require strong,…

In the context of the strong explosion of Industry 4.0, the metal casting industry - one of the fundamental industries - is constantly innovating to keep up with the trend.…