Since ancient times, people have known how to bond materials, seal, or protect surfaces by manually applying, spreading, or spraying adhesive using simple tools. This traditional method is commonly used in manual production, daily life, or tasks requiring flexibility that machines cannot handle. However, this approach heavily depends on the worker’s skill and carries inherent risks.

Therefore, with the continuous development of science and technology, a solution has been found to apply automation in glue application processes. Gluing automation is the process of using machinery and automated technology to perform glue application tasks that were previously done manually. This enhances productivity, precision, and efficiency in production while minimizing human errors.

Thanks to advancements in science and technology, modern automated systems are increasingly optimized in design while maintaining high efficiency. Typically, an automatic adhesive application system includes the following main components:

Implementing adhesive automation addresses the shortcomings of manual adhesive application while offering several outstanding advantages:

Automated adhesive systems are widely used across various industries, including:

Welding robots are widely used in manufacturing plants of various large and small scales. With a large investment capital, high requirements but bringing practical benefits to production activities and the…

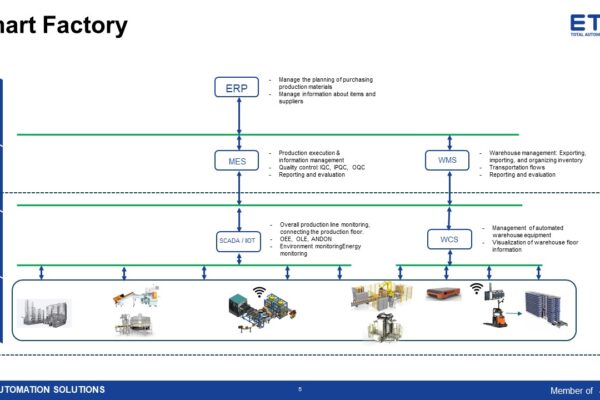

A smart factory is no longer just a trend but has become the new standard in modern manufacturing. It is a production facility that leverages advanced technologies such as IoT…

The Robotic Milling Solution utilizes industrial robots to perform high-precision milling and shaping operations with consistent accuracy and stable performance. The solution enables manufacturers to increase productivity, enhance design flexibility,…

Our Painting Solution provides an automated system for applying consistent and high-quality coatings to various products, ensuring a smooth and uniform finish every time. This solution is ideal for industries…