The factory previously relied entirely on manual labor, resulting in low productivity that could not keep up with increasing orders. Hiring additional workers to increase output would significantly raise costs and be deemed an impractical solution in the era of modern technology.

Manual operations in barcode labeling and verification led to frequent errors.

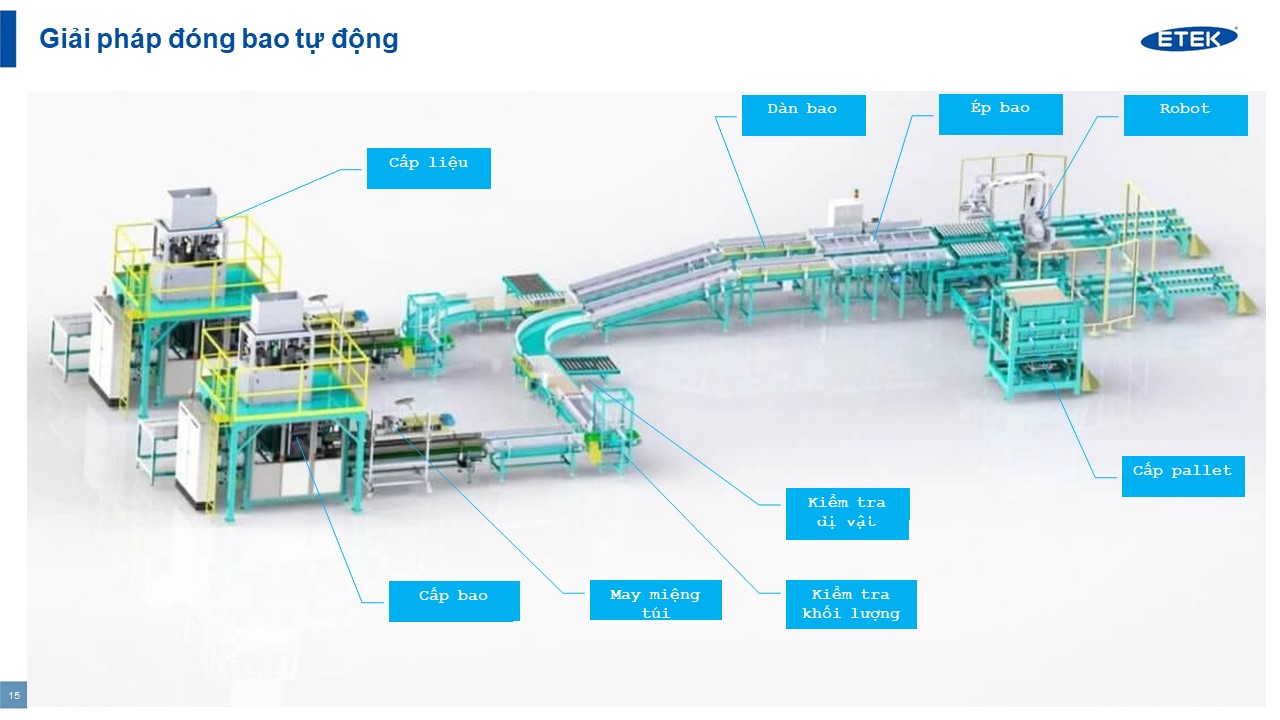

The customer required an automated line that seamlessly integrated bag sewing, weight measurement, product information printing, and automatic error detection through pallet stacking.

Production demands have intensified, requiring creative solutions to meet market needs and secure market share in a highly competitive environment.

Additionally, time pressure has increased—not only must factories produce adequate volumes, but they must also do so quickly and adapt to market fluctuations. Flexibility in adjusting production to market demand without compromising quality or increasing costs was essential.

Products needed to meet strict requirements for both weight and labeling to reduce costs associated with errors in manual processing.

The line had to ensure 100% safety during operation.

The automation of production lines marks a foundational customer’s desire to modernize and digitize their operations to stay compliant today.

After analyzing the customer’s requirements, ETEK implemented a comprehensive automation process, completing the project in just over four months. This included consulting, requirement analysis, technical design, project planning, installation, and final handover.

ETEK successfully built a fully automated bagging line with 1,200 bags per hour production capacity, capable of handling two bag types weighing 25kg and 50kg. The line was integrated with the latest technologies to maximize efficiency and flexibility.

Our automation system incorporates various advanced equipment and technologies, from automated transport systems to printing machines, information and weight-checking systems, and defective bag removal mechanisms. This ensures seamless and efficient production with minimal human intervention, enhancing automation across the entire process.

System Components