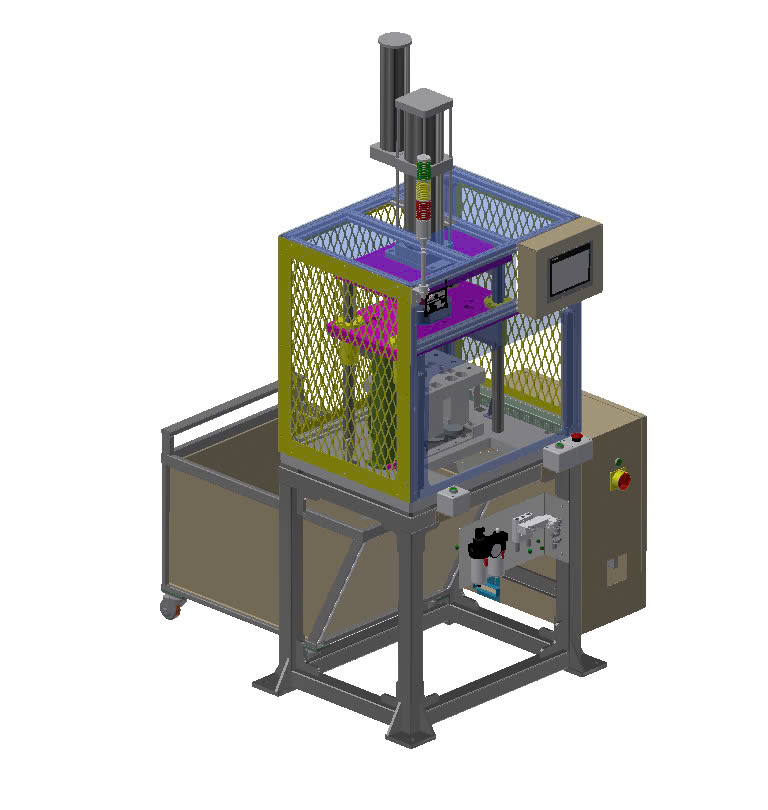

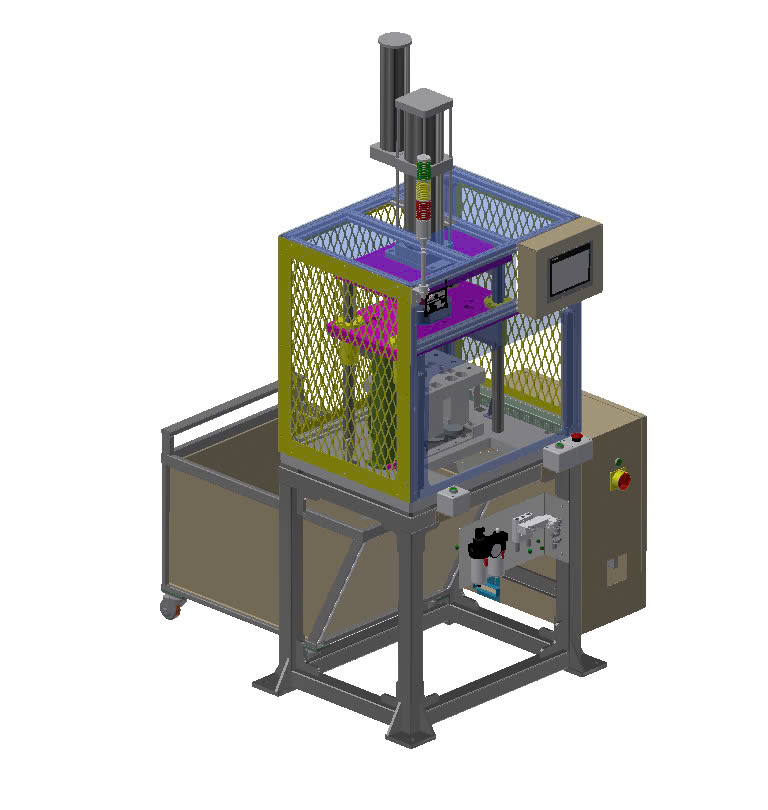

The Automatic Aluminum Pressing Machine utilizes pressing operations to shape and remove excess parts from the product after the aluminum casting process, ensuring the product meets technical specifications and aesthetic standards.

High Precision

Safety Mechanism

Flexible Adjustments

Robust Construction

Software-Controlled Management

Safety Mechanism: The Automatic Aluminum Pressing Machine is equipped with safety sensors at the door and safety guards around the cutting area, ensuring maximum operator safety.

Flexible Adjustments: The cutting head is interchangeable, allowing the machine to handle various product profiles efficiently.

Robust Construction: The entire machine frame is made of electrostatic powder-coated steel, making it durable and suitable for operation in harsh environments.

Software-Controlled Management: The internal software enables smart monitoring of metrics such as OEE, machine status, and energy consumption, providing a comprehensive view of operations for the operator.

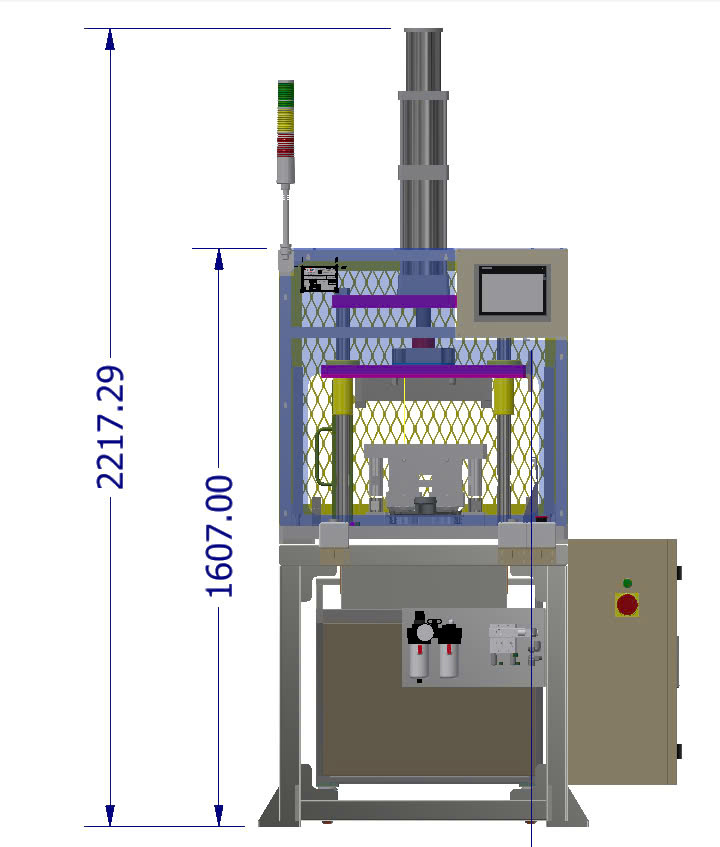

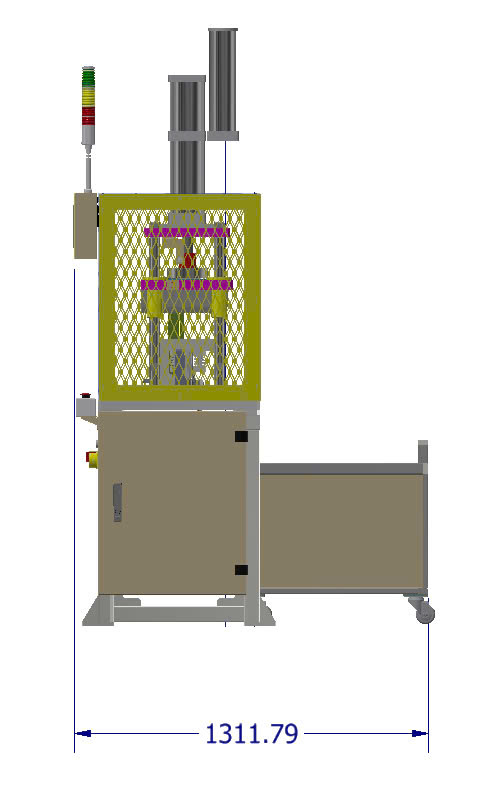

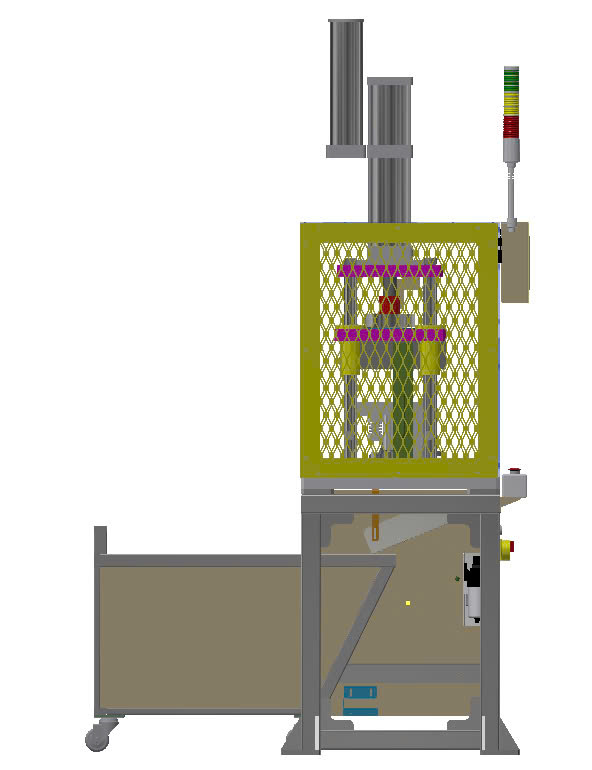

Technical Specifications

Layout