Welding robots are widely used in manufacturing plants of various large and small scales. With a large investment capital, high requirements but bringing practical benefits to production activities and the operation process.

The welding robot can perform MIG welding, TIG welding, and other difficult welding tasks. Industrial welding robots offer many benefits:

.jpg)

Consistent welding is a great advantage that attracts businesses to invest in welding robots. The quality of welds performed by industrial welding robots depends on both the quality of the material and the uniformity of the task process.

The application of welding robots in production systems brings much higher efficiency, high quality and stability than manual workers or skilled workers or experienced professionals.

MIG Welding Robot and TIG Welding Robot perform continuous tasks 24 hours a day, ensuring quality and systematizing the process. At the same time, eliminate the hazard factor when workers perform repetitive tasks in a toxic environment so that workers can focus on more difficult tasks that machines can’t do.

In any project or business of different sizes, waste significantly reduces the profitability of the business. This situation comes from any welder or error. Welding robots solve that problem, with high technology and precise specifications to ensure the correct metal cost for welding tasks, no matter how complex the task.

Besides, manual welding affects the aesthetics of the factory when the termites splash around. Cleaning up after welding takes time and affects the project progress as well as ensuring that the welding seams and the factory are clean and tidy, meeting the most demanding requirements of customers.

Fast, compact, aesthetic, and flexible are the advantages when applying welding robots in production. From there, businesses can use it to increase their competitiveness with other competitors in the market.

With nearly 20 years of pioneering automation solutions, ETEK provides welding robot solutions for manufacturing plants, bringing many advantages to businesses in the market. The early application of industrial welding robots is to seize the opportunity to develop and rise compared to other businesses in the same industry.

However, the selection of welding robots should pay attention to the cost, requirements and responsiveness of the factory, ETEK is a reputable unit for businesses to trust and bring the most suitable and complete solutions for each specific production purpose.

At ETEK, we have:

In the era of industry 4.0, automation is no longer an option but has become an inevitable trend. For mechanical factories, steel structures, automobiles and motorbikes, arc welding processes requiring…

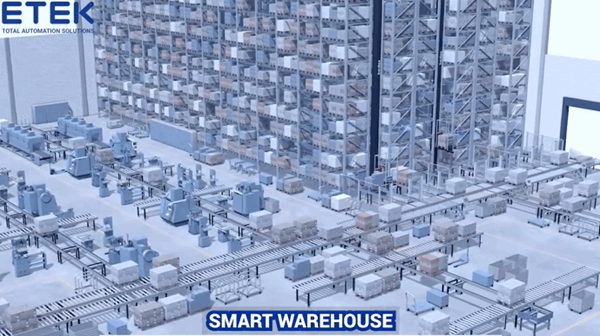

In the era of Industry 4.0, Intralogistics automation has become a key factor for businesses to optimize operational processes, reduce costs and improve productivity. Modern solutions such as smart warehouses, AGV/AMR robots and…

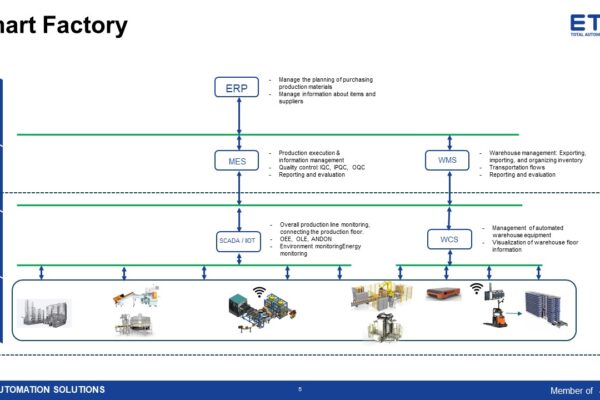

A smart factory is no longer just a trend but has become the new standard in modern manufacturing. It is a production facility that leverages advanced technologies such as IoT…

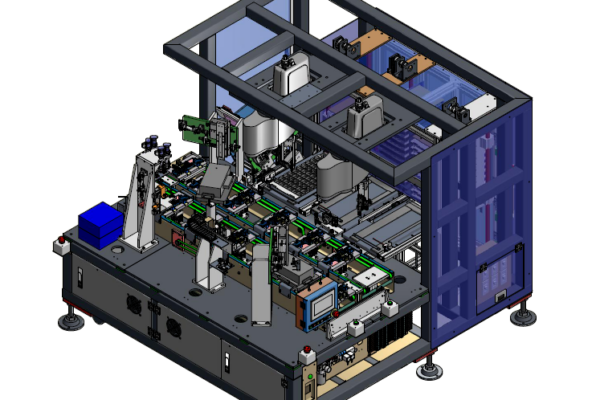

What is Automation Inserting? In our daily lives, we frequently encounter products assembled from numerous components, such as TVs, phones, laptops, and computers. The assembly process of these products involves…