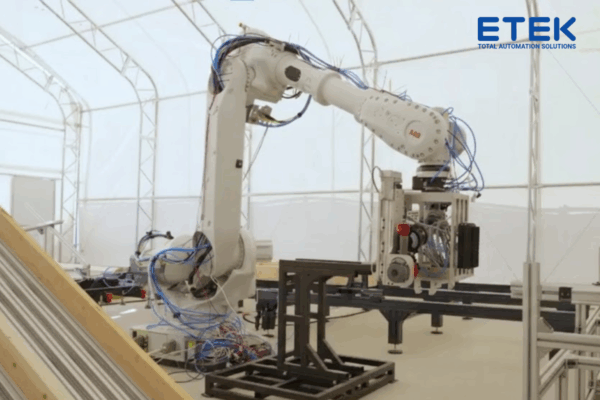

In modern industrial production, the gluing process is crucial for ensuring product quality, durability, and aesthetics. However, manual or semi-automatic methods often face limitations such as low precision, material waste, and heavy reliance on worker skills. To overcome these challenges, the 4-axis gluing machine was developed as an optimal solution, enhancing both production efficiency and product quality.

Watch the real video here:

With outstanding advantages, the 4-axis glue machine is an effective glue applicator solution, helping businesses improve their competitiveness in the era of smart manufacturing.

Contact ETEK now for detailed advice and experience the optimal glue application solution for your business!

In the era of digital transformation, the combination of robots and artificial intelligence (AI) is becoming a strategic solution, helping the construction industry improve productivity, reduce costs and ensure superior quality. One…

The application of automated laser welding combined with 6-axis robots is becoming a mainstream trend in modern manufacturing plants. This technology provides optimal solutions for precision welding requirements on many different types of materials.…

Entering the industrial revolution 4.0, many businesses around the world are gradually focusing on investing in the development and production of service (support) robots. Industrial welding robots are one of…

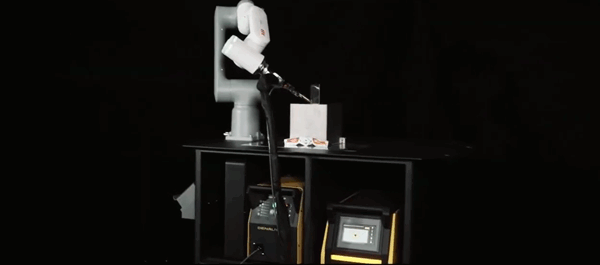

In the context of the electronics industry increasingly requiring flexibility, speed and high quality, ETEK introduces a semi-automatic LCD screen assembly line solution , applying the advanced Collaborative Automation model -…