In the era of industry 4.0, motorbike and automobile manufacturing enterprises increasingly focus on automation, improving productivity and stabilizing product quality. Especially, with products such as motorbike frames – the main load-bearing part, investing in a high-quality industrial painting line is extremely necessary.

Understanding that need, ETEK, with more than 20 years of experience providing industrial automation solutions, is proud to bring a modern, economical and efficient motorcycle frame painting line solution – which has been successfully deployed and operated stably.

Automatic painting line helps ensure uniform coating, durable color, high anti-rust and anti-corrosion ability , enhancing the aesthetics of the product.

The system operates continuously and accurately, shortening painting and drying time, increasing capacity, reducing labor , and minimizing human errors.

ETEK designs a closed automatic painting line system , including the main stages:

Remove grease, dirt, rust to create cleanliness before painting.

The anti-rust paint has high adhesion, covering the entire surface, including hidden corners – a popular technology in the automobile and motorbike industry today.

Fix the electrophoretic paint layer with a modern drying oven system, precise temperature control.

Bring the chassis temperature to a stable level before moving on to the next step.

Surface preparation for the next coat of paint includes light surface treatment, removal of dirt, and application of a sealing coat to increase adhesion.

To increase the adhesion of the final coating, helping the glossy paint last longer.

Allow excess solvent to drain before complete drying.

The outermost coating protects the car frame from scratches, oxidation, increases shine and aesthetics.

Products are automatically and safely removed from the system.

Ensure finished products meet standards, ready for assembly or packaging

ETEK’s motorcycle frame painting line solution is not only applicable to traditional motorbikes or scooters, but also suitable for modern products such as:

We are committed to accompanying businesses from AZ, including:

A team of experienced engineers with in-depth knowledge of automation technology and production processes, always ready to accompany, advise and provide timely technical support – from the ideation stage, implementation to system operation and improvement.

Don’t let outdated paint lines affect your product quality and competitiveness. Let ETEK become your trusted technology partner , conquering the market with international standard products.

Send a consultation request or contact the hotline to receive a capacity profile and the most suitable solution for your factory.

In modern production environments, accuracy and speed are key factors in determining efficiency. The automatic bottle feeding machine (Bottle Feeding) has emerged as an outstanding solution to automate the bottle…

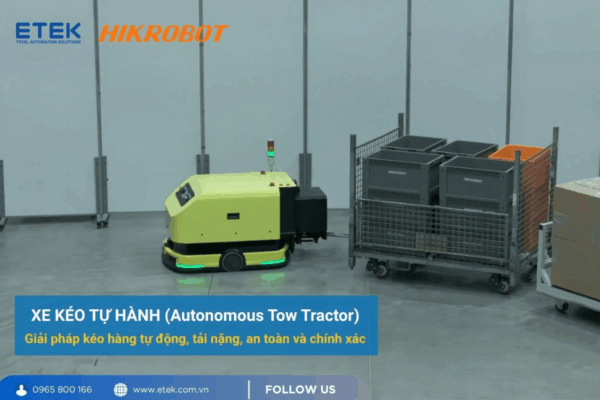

In the context of modern manufacturing increasingly requiring high productivity, safety and comprehensive automation, Autonomous Mobile Robots (AMRs) are gradually becoming an indispensable part of the internal logistics chain at the factory.…

In modern automotive manufacturing, the painting process not only enhances aesthetics but also plays a critical role in determining product durability and overall value. ETEK provides a total automotive body…

What is automation in the garment industry? The application of automation technology is a trend that textile companies are particularly interested in and are urgently promoting investment in. This is…