Both Cobots and Industrial Robots represent advanced automation technologies, each suited to specific production requirements. At ETEK, we provide optimized automation solutions that help manufacturers improve productivity and operational efficiency domestically and internationally.

In the field of industrial automation, the “Cobot trend” is reshaping how businesses operate. Collaborative Robots (Cobots) emerged over a decade ago and quickly gained popularity thanks to their affordability and ease of deployment compared to traditional industrial robots that often require substantial investment.

However, to successfully implement automation, companies must carefully assess their operational needs and production characteristics. With the rapid evolution of robotics technology, the gap between collaborative and traditional robots continues to narrow, driven by advances in control, sensing, and safety systems.

Cobots are becoming a leading trend in modern manufacturing automation. Yet, there remain several misconceptions about their performance, speed, and safety. Below are six key insights to help you better understand Cobots and how they empower businesses to achieve higher productivity.

Cobots are compact, lightweight, and user-friendly. Unlike conventional industrial robots, they can be easily integrated with other machines via PLCs or programming software, offering greater flexibility and adaptability in automation.

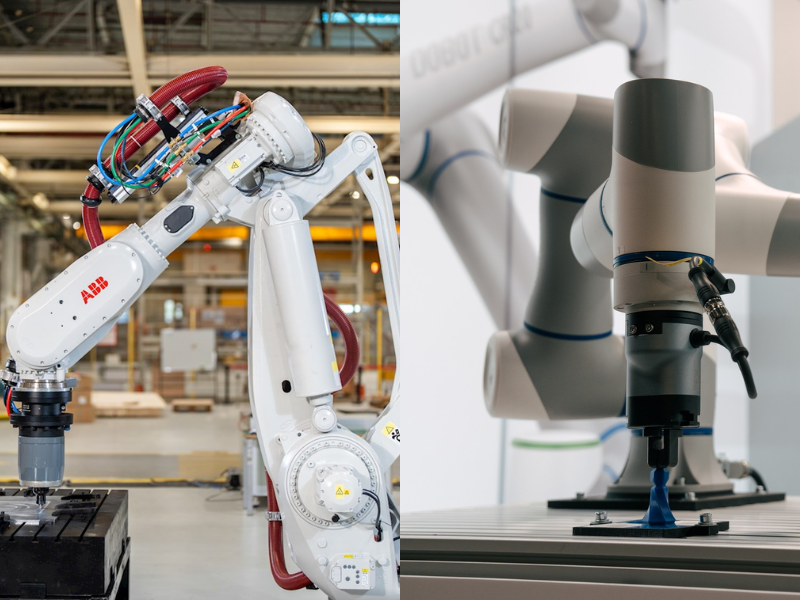

A standard industrial robot can be configured for collaborative tasks if it complies with the safety requirements outlined in ISO/TS 15066. However, only Cobots are specifically designed for human-robot collaboration from the ground up, equipped with built-in safety functions, intuitive operation, and enhanced flexibility.

Although Cobots are designed to work alongside humans, proper safety measures such as light curtains, safety mats, or speed reduction when operators enter the workspace are still necessary. Thanks to modern safety technologies, most Cobots today can operate without safety fences, offering higher flexibility and space efficiency – examples include leading Cobot models from ABB, Dobot, and others.

Instead of replacing workers, Cobots handle repetitive or hazardous tasks, allowing employees to focus on higher-value work. Implementing Cobots not only boosts productivity and product quality but also strengthens a company’s competitiveness in the global market.

When combined with appropriate safety systems, Cobots can operate faster than humans while automatically slowing down or stopping when needed. They deliver consistent, precise performance and are particularly effective in production processes where speed, reliability, and accuracy are critical.

Modern Cobots achieve repeatability levels of 0.01–0.05mm, making them ideal for electronic assembly, finishing operations, and other precision-demanding applications. With integrated force/torque sensors, Cobots can optimize cycle time and reduce production errors.

Both Cobots and traditional Industrial Robots offer unique advantages suited to different levels of automation and production requirements. Choosing the right type of robot helps manufacturers maximize productivity, improve quality, and reduce operating costs.

At ETEK, understanding the distinctive features of Cobots and Industrial Robots is the key to implementing automation solutions that are efficient, scalable, and sustainable for the future.

In the context of the mobile phone manufacturing industry increasingly requiring high speed and precision, the application of automation technology to the product quality inspection line is becoming an inevitable…

The case erector machine plays a critical role in automating the packaging process, offering a fast and reliable solution for businesses to prepare boxes for product packaging. This article will…

Modern laser engraving machines have become indispensable tools in various manufacturing and processing industries due to their ability to cut, engrave, and mark with exceptional precision and speed. This technology…

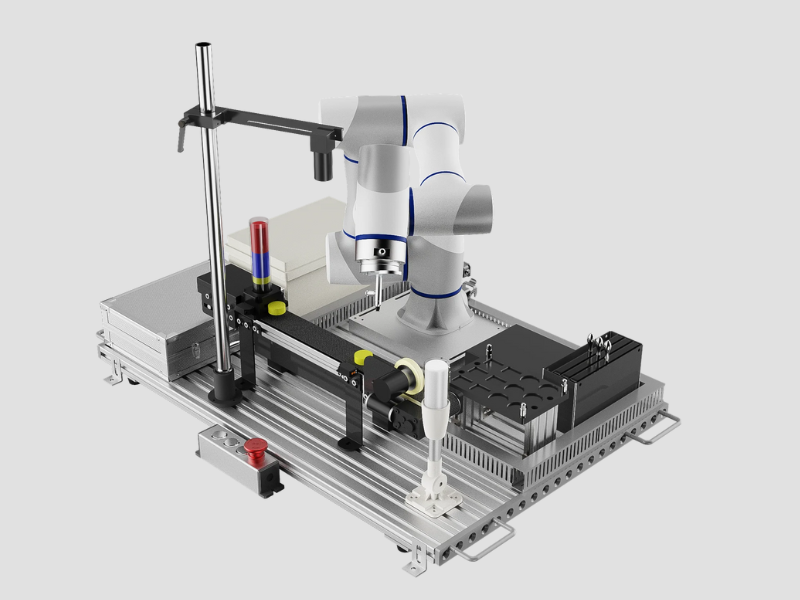

The cobot-based automatic machine tending solution feeds raw parts and finished products into CNC machines, replacing repetitive, high-precision tasks while ensuring safe collaboration with human workers. What is Cobot Machine…