You may be familiar with traditional warehouses that offer spacious, open spaces for receiving and storing goods. However, with the development of technology, smart warehouses were born to help perform these tasks much faster and more effectively.

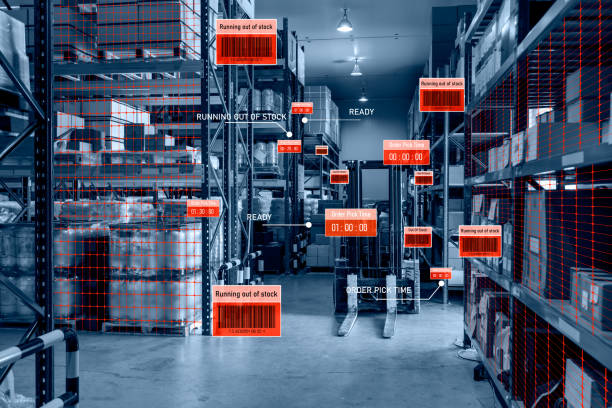

Essentially, smart warehouses refer to the combination of Artificial Intelligence, Robotics, and the Internet of Things (IOT) to automate and digitize operations that rely heavily on manual labor and paper-based processes. sheets of traditional warehouse.

If you are a business looking to improve warehouse operations, this article is for you, follow the article below to not miss detailed information about smart warehouses and important applications. for businesses.

Smart warehouse can be understood as an area where goods and materials are stored using technology or machinery to carry out warehouse activities.

Smart warehouses can handle requests more quickly than traditional models. Warehousing activities such as order receiving, counting goods, and storing goods are all carried out more accurately with smart warehouses.

Smart warehouses can combine various automation technologies such as warehouse management systems (WMS), IOT sensors, and Automation Robots to build a technological environment in which goods and warehousing requirements are received, sorted, identified, sorted, and finally prepared for transportation are all automated.

Currently, based on the specific needs and conditions of businesses, smart warehouses can be designed and installed to suit the needs of each business.

Smart warehouses provide optimal solutions, improving operational efficiency with many outstanding benefits. Taking advantage of modern technology, warehouses not only save costs but also increase overall efficiency.

Thanks to smart design, the warehouse can take advantage of height to stack goods, thereby maximizing the usable area by up to 80% compared to traditional warehouses. This not only ensures safety but also significantly increases warehouse capacity, allowing for the storage of far more pallets.

Moreover, an automated warehouse system further reduces the need for manual labor. As a result, businesses can save up to 50% of human resources compared to traditional warehouses, with only a small team needed to manage and operate the system.

Modern support equipment such as smart scanners, automatic delivery robots or conveyor systems help reduce order processing time much faster.

Each pallet in the warehouse is managed by a unique identifier, allowing the exact location and product information to be determined, thereby minimizing labeling errors, loss or errors in importing and exporting goods.

Implementing a smart warehouse system offers the ability to effectively reduce operating costs through automating processes. With the support of advanced technology, the need for manual labor is significantly reduced, helping businesses save on personnel budgets.

In addition, the modern inventory management system ensures high accuracy, minimizing data loss or distortion, thereby minimizing unnecessary losses.

Smart system updates warehouse information in real time, fully displaying data such as product quantity, inventory status or storage location… This helps businesses quickly grasp the situation and promptly handle any arising problems.

With fast and accurate import and export processes, smart warehouses help shorten delivery time and increase accuracy in order processing. This not only improves customer experience but also helps businesses meet increasing market demands.

With RFID technology, barcodes and integrated sensors built into smart warehouses, businesses can easily track the flow of products throughout the supply chain response. From there, production and distribution planning becomes more accurate, avoiding surplus or shortage of goods.

>>> Smart warehouses are an indispensable solution in the 4.0 technology era, bringing outstanding competitive advantages to businesses. If you are looking for an optimal warehouse model, please contact ETEK immediately for advice on the most suitable solution.

When business organizations convert to smart warehouses, they can realize the outstanding benefits that this system brings, but must also recognize the limitations. of smart warehouses such as:

Smart warehouses generate large amounts of data related to inventory, operations, and customer information. Without effective security measures, businesses may face the risk of unauthorized access, information leakage or violation of security regulations.

This is a significant risk that businesses need to focus on addressing to ensure customer trust and data security.

Transitioning to smart warehouses is not simply about integrating technology but also requires a comprehensive change in operations. This includes reshuffling staffing and providing training to familiarize the workforce with and effectively use the new systems.

However, this process is often costly and time-consuming, especially for businesses with a large number of employees or not familiar with modern technology.

In general, when choosing a smart warehouse solution, businesses need to carefully evaluate these limitations and develop an appropriate overcoming plan to maximize efficiency and minimize risks.

The AS/RS warehouse is a system specifically designed to automate the storage, import, and export activities of goods in smart warehouses. It includes product storage racks and automated handling equipment, such as stacking cranes, which move goods in and out of shelves.

Furthermore, conveyor belts connecting entrances and exits help transport goods smoothly and quickly throughout the warehouse, thereby optimizing storage space and improving overall efficiency.

AGV and AMR are automated vehicles that move in warehouses, helping to transport goods without human intervention. They use sensors and automated navigation systems to move goods to different locations in the warehouse, thereby reducing labor costs and increasing operating speed.

Smart conveyors help move goods in the warehouse efficiently and automatically. These conveyor systems can automatically adjust the flow of goods and coordinate with other technologies such as AGVs, making the process of transporting goods seamless and fast

The Pick to Light system uses LEDs or light signals to guide workers in selecting the correct goods, thereby improving picking speed and accuracy. This system is very effective in reducing errors and improving productivity in warehouses with large quantities of goods.

Kardex offers smart warehouse solutions that integrate automated storage and retrieval with real-time warehouse management. These systems help optimize storage space while minimizing human intervention. Additionally, Kardex solutions are highly scalable, making it easy to expand as warehouse needs grow.

WMS software (Warehouse Management System) is an important tool in smart warehouse management. It helps track inventory in real-time, optimize storage and retrieval processes, and ensure warehouse operations are carried out accurately. WMS can integrate easily with a business’s existing software systems and is flexible in meeting different requirements

Besides warehouse management software (WMS), other software like ERP, MES, and OEE also play a crucial role in smart warehouses.

ERP software is a comprehensive solution that helps businesses manage every aspect of their operations, from production, finance, human resources, to warehousing. ERP integrates data from many different departments into a single system, helping to increase connectivity between processes. In smart warehouses, ERP helps synchronize goods information, optimize inventory planning and improve demand forecasting.

MES is real-time production process monitoring and management software. In smart warehouses, MES helps track the production and consumption of goods, ensuring that all products are produced and shipped on schedule. MES provides data on the performance of each process, helping businesses quickly detect problems and provide timely solutions.

OEE is an important indicator that helps measure the performance of equipment in the warehouse. OEE software monitors and evaluates equipment usage efficiency, calculates the actual operating rate of machines, thereby helping businesses identify weaknesses and optimize resource usage.

In smart warehouses, the use of OEE helps improve the operational efficiency of automated systems such as AGVs, conveyors and automatic handling equipment. Thanks to OEE, businesses can reduce equipment downtime and improve operational productivity

All of these technologies play a crucial role in transforming traditional warehouses into smart warehouses, enhancing operational efficiency and reducing costs. Businesses should identify their needs and development goals to select the appropriate solution, optimizing processes and boosting productivity.

ETEK hopes that the detailed information shared above will give you a comprehensive overview of the current smart warehouse solution. If you are in need of implementing a smart warehouse system for your business, please contact ETEK immediately through the information below for detailed advice!

The Pick to Light system integrated into automotive assembly plants is an efficient solution that helps workers quickly and accurately select components, reducing errors and improving productivity. Understanding the Pick…

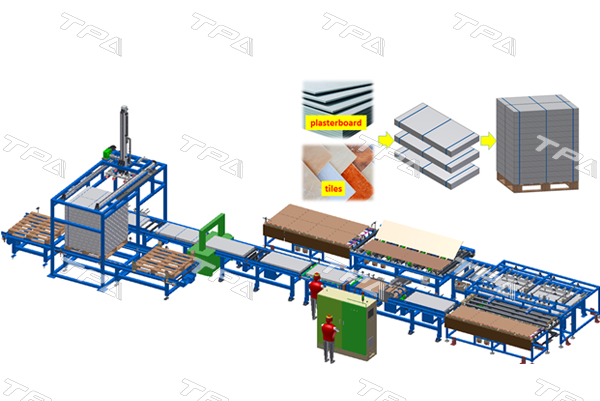

DESCRIPTION Application Packaging, pallerizing Professions CPG, F&B, Metal, Auto, Construction.. PRODUCTS Description Large & heavy products : tiles, plasterboard… Dimensions (max) (mm) 600 x 1200 x 100* Weight (max) (kg)…

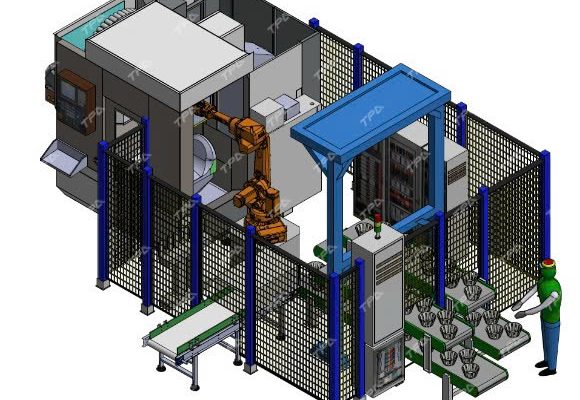

Our Stamping Solution provides an efficient, high-speed method for producing stamped components from metal and plastic materials. Using automated stamping machines, robots, sensors, vision systems, conveyors, etc., to meet the…

Wide Flexibility With the FlexGripper – Vacuum, ABB’s IRB 660 and IRB 460 palletizing robots can operate even more efficiently in end-of-line palletizing applications. The FlexGripper can handle up to…