The KR SCARA robot is a high-performance industrial robot, distinguished by its powerful operation and exceptional speed in modern production lines. For applications such as small-part assembly, material handling, and quality inspection, the ultra-compact design of the KR SCARA robot optimizes installation space while delivering high efficiency and cost-effectiveness from the very beginning of deployment.

Developed to meet automation requirements in space-constrained manufacturing environments, this 4-axis SCARA robot enables fast, precise, and highly repetitive movements. Thanks to its integrated media supply system, the robot can be easily connected to peripheral devices, allowing manufacturers to effectively control investment and operating costs.

– Payload: 6 kg and 12 kg

– Reach: Optimized from 500 mm to 700 mm

– Cycle time: 0.36 seconds (500 mm reach), 0.38 seconds (700 mm reach)

– Operating temperature: Stable operation from 5°C to 40°C

– Standards: CE compliant, IP20; cleanroom version available with ISO 5 certification (IP54)

– Optimized design: Slim profile, lightweight construction, and minimal footprint—ideal for compact robot cells

– Smart integration: Internal media supply (air, power, data) enables clean, safe, and efficient integration of peripheral devices

– Safety & reliability: Equipped with the compact KR C5 micro controller, ensuring high reliability in various operating environments

– ESD compliance: Standard electrostatic discharge protection, particularly critical for electronics manufacturing

– Easy standardization and scalable production lines

– Reduced dependence on highly skilled labor

– Improved process stability and repeatability

– High flexibility when changing products or processes

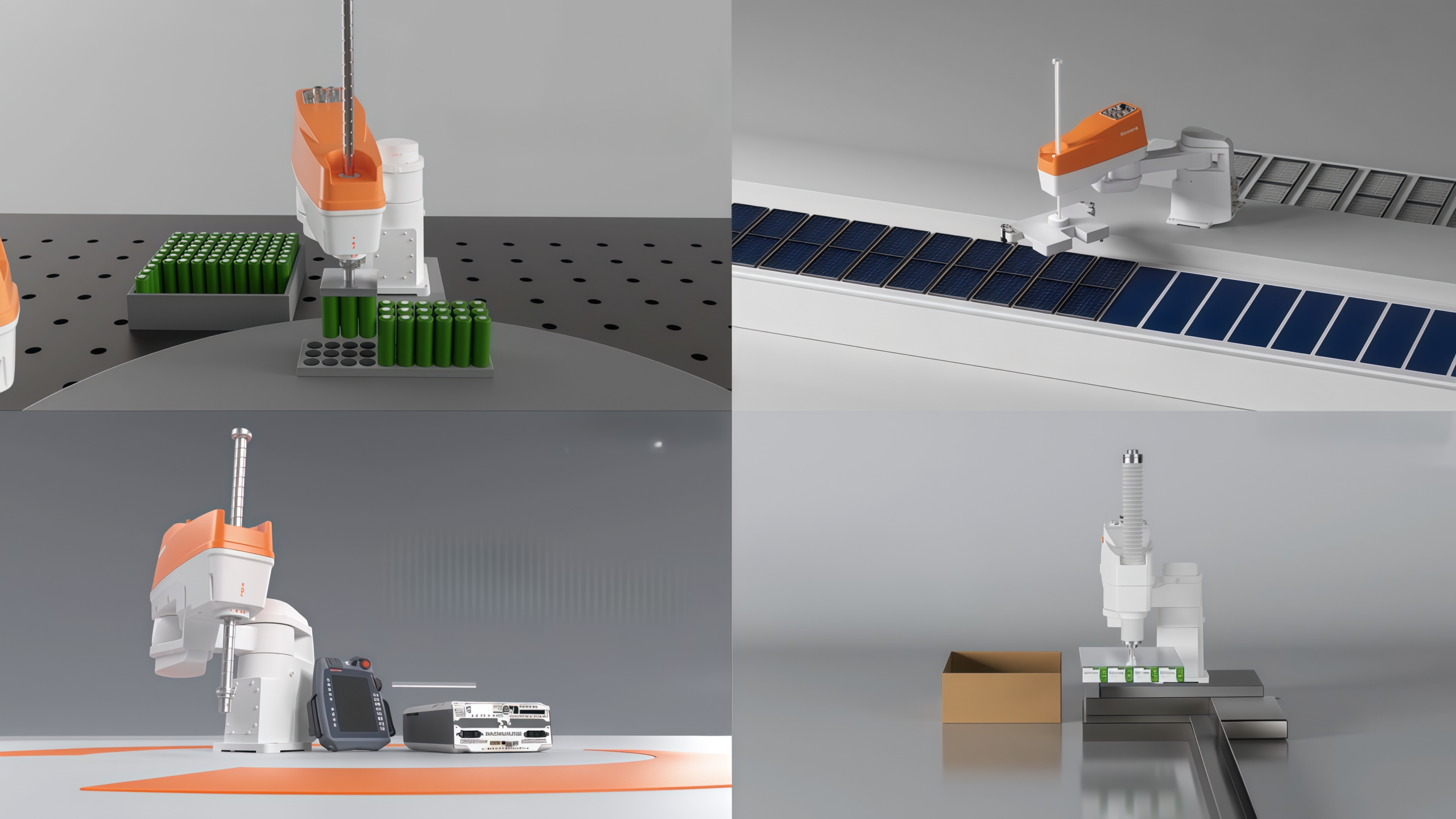

– Palletising: The SCARA robot ensures fast and precise stacking operations, accelerating end-of-line packaging while maintaining high stability and repeatability.

– Part Handling: With fast and accurate motion, the robot efficiently transfers components between processes, reducing waiting time and optimizing production flow.

– Material Handling: The SCARA robot supports consistent movement, sorting, and positioning of materials, increasing productivity and reducing errors in automated processes.

– Measurement and Inspection: Thanks to high repeatability, the robot ensures accurate and stable measurement positions, improving the reliability of quality inspection results and reducing reliance on manual operations.

– Small-Part Assembly: The robot performs high-speed assembly tasks with consistent precision, making it especially suitable for small components in electronics, electric vehicle manufacturing, and high-volume production lines.

Contact ETEK for more detailed consultation

Let ETEK partner with you from assessment – design – manufacturing – installation – technology transfer.

Address: 189 Phan Trong Tue Street, Thanh Liet Ward, Thanh Tri District, Hanoi, Vietnam

Hotline: 0965800166

Email: info@etek.com.vn

Website: https://etekautomation.com.vn

In the context of increasingly fierce competition, optimizing warehouse operations is a key factor to help businesses improve efficiency, reduce costs and serve customers faster. One of the advanced technology…

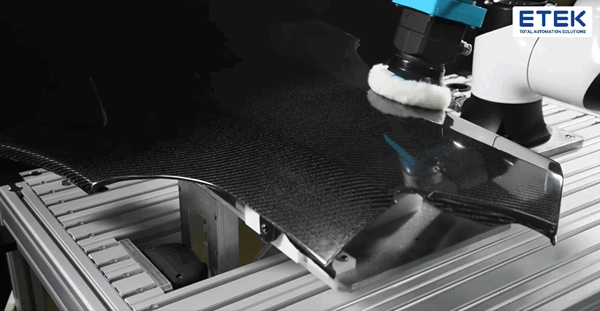

In the era of smart manufacturing, metal polishing automation is no longer a trend but has become a core solution to help factories improve product quality, optimize costs and increase…

As manufacturing and logistics businesses increasingly focus on efficiency and accuracy, smart warehouse solutions are becoming a strategic choice to improve performance, save space and ensure safe operations. The Kardex…

The case erector machine plays a critical role in automating the packaging process, offering a fast and reliable solution for businesses to prepare boxes for product packaging. This article will…