Integrating the Color Pick System into picking operations enhances workforce flexibility and enables businesses to handle sudden increases in order demand.

The Kardex Color Pick System is a simple and flexible pick-to-light solution that integrates seamlessly with any existing Kardex Remstar intelligent storage system, allowing companies to scale their workforce and workflows to meet growing operational needs. Based on the principles of pick-to-light technology, the Color Pick System guides multiple operators through the picking process using colored indicator lights, allowing you to easily add or reduce labor resources according to current order volumes.

When demand is high, the Kardex Color Pick System allows multiple operators to pick items from designated work zones using pick-to-light technology to achieve higher productivity. When demand decreases, the system can be operated by just one worker. This flexibility makes it easy to scale your workforce according to peak picking requirements.

The Kardex Color Pick System combines multiple orders into a single batch that can be processed simultaneously. This innovative concept adds color lights to the batch picking process, allowing several operators to pick items from the same workstation at once.

The system can achieve throughput rates of up to 300 picks per hour per operator, delivering a highly productive and dynamic group picking strategy. With multiple workers in the same area, several order batches can be completed simultaneously to maximize output.

With the Kardex Color Pick System, labor resources can be flexibly scaled to meet order demands at any given time.

For example:

On Mondays, when order volumes are high, up to six operators can be added to manage demand.

On Tuesdays, when order volumes drop by 30–40%, the workforce can be easily adjusted to four operators.

By using the Kardex Color Pick System, businesses can effortlessly adapt their labor allocation to match real-time order requirements.

Additionally, operators can be trained very quickly, as the system is intuitive and requires minimal training to operate effectively.

For more information, please contact ETEK.

Palletizing robots and pallet-stacking robots are becoming increasingly important in manufacturing plants, effectively fulfilling the final task of automated line for stacking goods onto various types of pallets. The application…

https://www.youtube.com/watch?v=CueLwlbNOeQ Challenges in Traditional Warehouse Management In today’s increasingly competitive environment, manufacturing and logistics companies are facing numerous challenges in warehouse management: Warehouses are full but still short of space:…

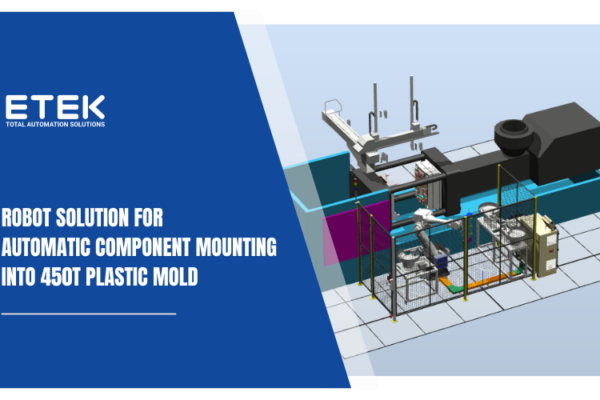

Introduction to automatic component mounting robots into plastic molds The robot solution for attaching components (Component insert robot solution) automatically to the 450T plastic molding mold helps automate the process…

Our Painting Solution provides an automated system for applying consistent and high-quality coatings to various products, ensuring a smooth and uniform finish every time. This solution is ideal for industries…