In the era of smart manufacturing, metal polishing automation is no longer a trend but has become a core solution to help factories improve product quality, optimize costs and increase productivity. With the ability to process every small detail accurately and evenly, this technology has completely replaced traditional manual methods, contributing to bringing the industry closer to the 4.0 standard.

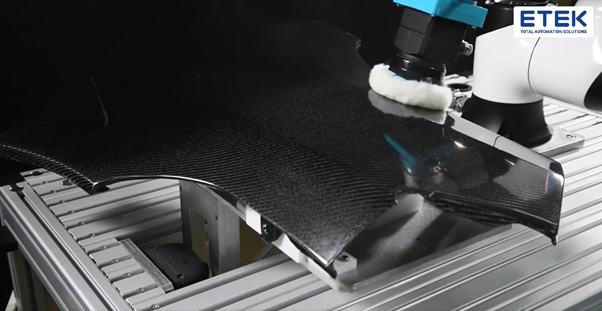

The system is automatically programmed to process metal surfaces with high precision, ensuring uniformity on each product – something that is almost impossible to achieve by manual methods.

The automatic metal polishing machine is capable of operating continuously 24/7 without affecting quality, helping to optimize the production line and reduce downtime.

All products after processing meet the same quality standards, regardless of the worker’s skills.

Eliminating manual operations helps to minimize work accidents, especially when working with sharp materials or high-risk environments.

This technology is widely applied in many modern manufacturing fields:

We provide a complete package of metal polishing automation solutions including:

Investing in an automated metal polishing system not only brings economic efficiency but also contributes to building a professional brand image:

Contact us for advice on the most suitable solution for your factory!

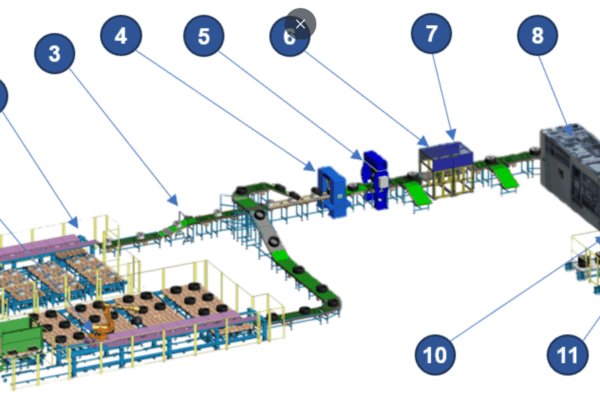

The automotive industry demands high-volume tire manufacturing solutions that deliver exceptional speed, consistency, and reliability. ETEK Automation provides comprehensive tire assembly line systems that integrate advanced automation technology to meet…

In modern manufacturing, packaging automation optimizes processes, enhances productivity, and reduces costs. Automated packaging systems handle tasks like filling, sealing, labeling, and palletizing with high precision and speed, making them…

Integrating the Color Pick System into picking operations enhances workforce flexibility and enables businesses to handle sudden increases in order demand. The Kardex Color Pick System is a simple and…

Over the years, traditional industrial robot system have played a vital role in automating polishing and finishing processes. However, as the demand for flexibility and cost optimization continue to grow,…