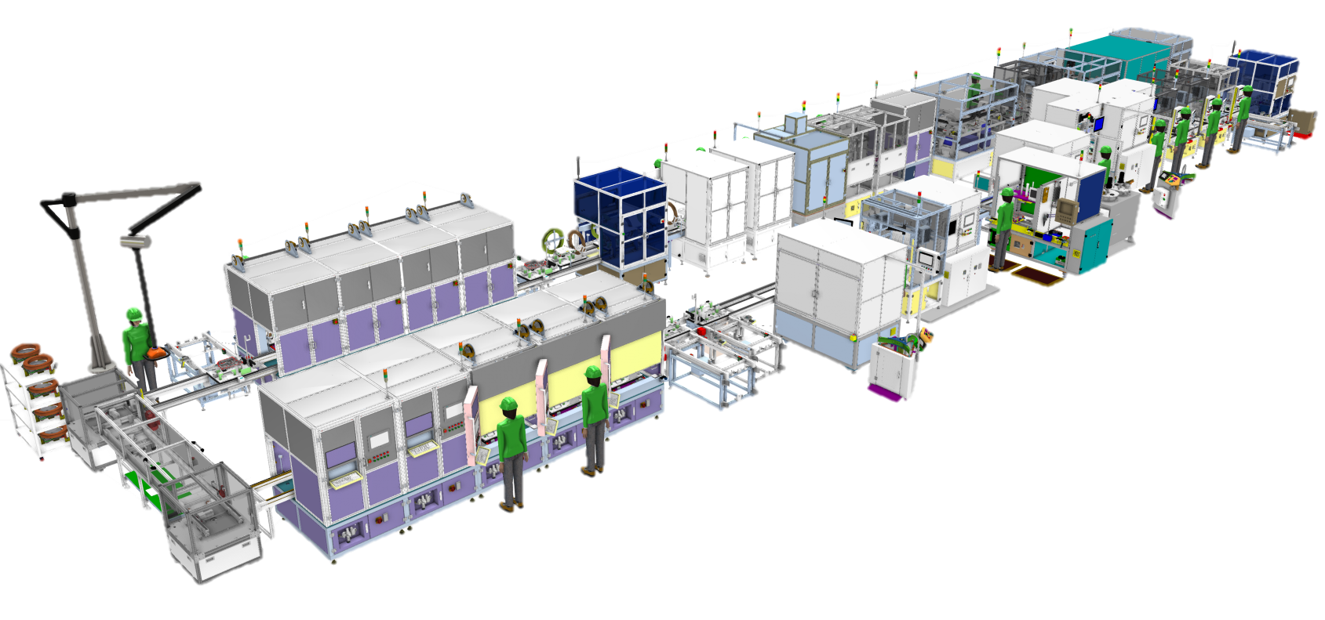

In today’s rapidly evolving electronics industry, remote control devices are essential components across automotive and consumer electronics sectors. The demand for high-volume production with consistent quality requires sophisticated automation solutions. ETEK Automation delivers comprehensive remote control assembly line systems that integrate cutting-edge technology to meet the most demanding manufacturing standards.

Our remote control assembly line serves diverse manufacturing needs across multiple industries, producing high-quality remote control devices for automotive applications including car key fobs and vehicle remotes, consumer electronics such as TV remotes and audio equipment controllers, industrial control systems, and smart home automation devices. The automotive and transportation sector benefits from our precision manufacturing of vehicle electronics and keyless entry systems, while the consumer electronics industry relies on our solutions for home entertainment systems and smart device controllers. This versatility makes our assembly line an ideal solution for manufacturers serving both B2B industrial clients and consumer markets, ensuring consistent quality and performance across all remote control device categories.

Our assembly line features an integrated 11-step sequential process designed for maximum efficiency and quality:

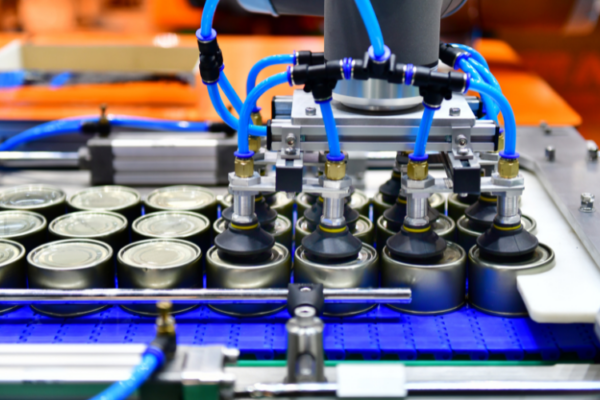

Automated component feeding and positioning system using precision conveyor mechanisms and robotic arms for accurate placement of components.

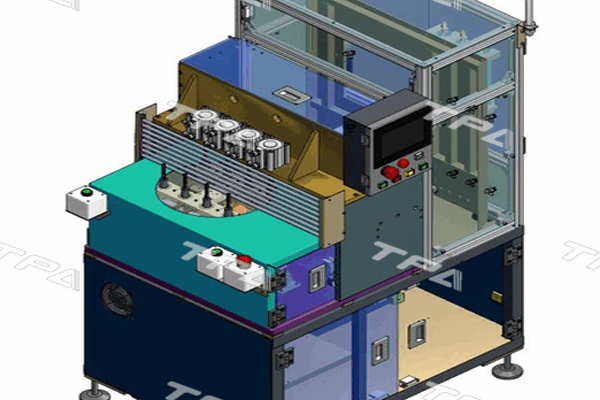

High-precision dispensing systems apply bonding agents with micron-level accuracy using programmable patterns and real-time flow monitoring.

State-of-the-art laser systems provide permanent product identification, serial numbers, and logos with automatic focus adjustment and verification.

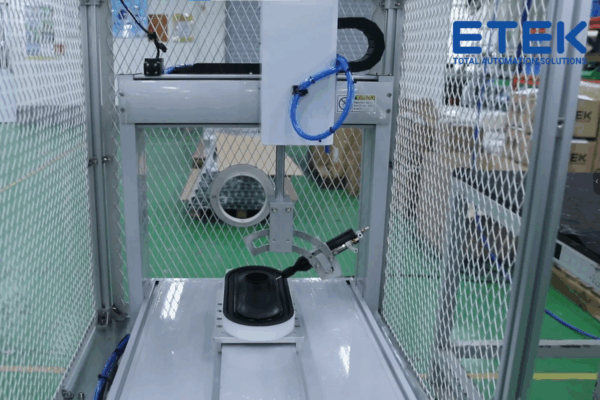

Automated component placement using high-precision robotics with force feedback control for accurate assembly of electronic components and mechanisms.

Additional precision bonding processes enhance durability through strategic application of structural adhesives with specialized dispensing heads and curing.

Protective layer application using automated spray coating methods with environmental controls and thickness measurement for consistent protection.

Secure component fastening using automated screwdriving systems and ultrasonic welding with torque-controlled fastening for reliable connections.

Final assembly coordination integrating all components using precision robotics with automated testing to verify proper connections and functionality.

Advanced soldering systems create reliable electrical connections using selective wave soldering with automated flux application and inspection.

Efficient product handling for smooth transfer of completed units with automated orientation systems and gentle handling mechanisms.

Extensive testing including functional testing, RF signal verification, battery testing, and visual inspection using automated go/no-go protocols

ETEK Automation delivers comprehensive electronics manufacturing automation with advanced technology integration including laser systems, precision dispensing, and automated testing. Our solutions ensure cost-effective production with rapid ROI while maintaining quality assurance through built-in inspection systems at every manufacturing stage.

Get Your Custom Remote Control Assembly Line

Transform your production capabilities with ETEK’s automation solutions. Our expert team provides end-to-end support from initial consultation through implementation and ongoing maintenance.

Refer to ETEK’s completed projects HERE

Contact ETEK Automation Today:

Address: 189 Phan Trong Tue Street, Thanh Liet Ward, Thanh Tri District, Hanoi, Vietnam

Phone: 0965 800 166

Email: info@etek.com.vn

Website: https://etekautomation.com.vn

In modern industrial production, the gluing process is crucial for ensuring product quality, durability, and aesthetics. However, manual or semi-automatic methods often face limitations such as low precision, material waste,…

What is Automated Glue Applicator? Glue application automation is the use of glue application robots, cobots (collaborative robots) and intelligent control systems to perform the glue application process on the product…

What is automation in the metal industry? The metal industry is one of the most versatile industries and is therefore identified as a priority for robot-based automation solutions. This sector…

Rising labor costs, inconsistent production efficiency, and errors in processing and packaging are becoming major challenges for instant food manufacturers. Given these difficulties, finding optimal solutions to enhance production efficiency…