In the context of the electronics industry increasingly requiring flexibility, speed and high quality, ETEK introduces a semi-automatic LCD screen assembly line solution , applying the advanced Collaborative Automation model – where humans and Robots/Cobots work together to achieve outstanding efficiency.

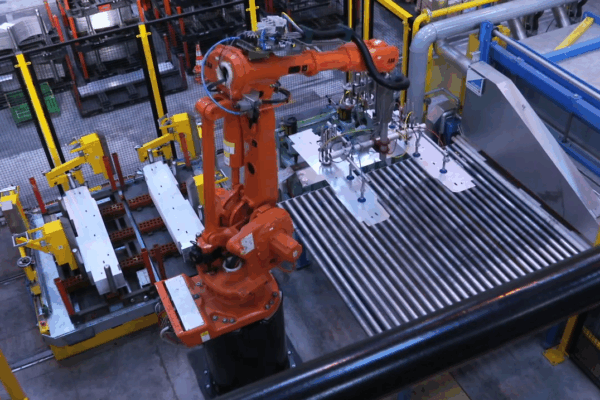

In this semi-automatic line, Robots/Cobots undertake repetitive steps and can be flexibly programmed according to each product model, specifically:

.png)

Instead of performing monotonous manual operations, workers are assigned to stages that require assessment, monitoring and flexible processing:

Special solution suitable for manufacturing businesses:

With experience in integrating automatic, semi-automatic production lines and robot/cobot systems, ETEK not only provides equipment but also consults on optimal solutions, helping businesses transform quickly, effectively and sustainably.

In the context of the strong explosion of Industry 4.0, the metal casting industry - one of the fundamental industries - is constantly innovating to keep up with the trend.…

In the context of the booming Industry 4.0, metal stamping automation is no longer an option but a mandatory trend if businesses want to increase productivity, ensure quality and minimize labor risks. Industrial…

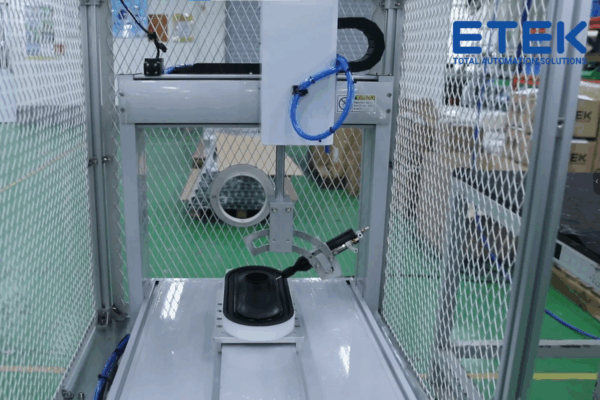

In modern industrial production, the gluing process is crucial for ensuring product quality, durability, and aesthetics. However, manual or semi-automatic methods often face limitations such as low precision, material waste,…

What is CoLOS Software? CoLOS software is an intelligent solution designed to manage and optimize printing and coding activities on packaging. With its comprehensive integration capabilities, the software helps businesses…