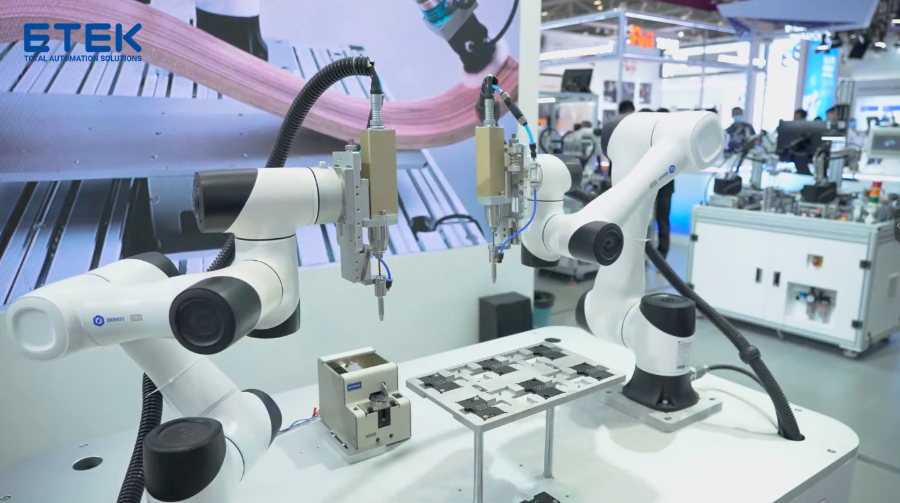

The automatic screwdriving cobot solution for automated assembly lines enables safe human–robot collaboration without the need for safety fences, ensuring high precision, stable productivity, continuous operation, and ease of use.

This advanced cobot-based screwdriving solution is specifically designed to meet the stringent requirements of modern manufacturing. The system not only delivers high accuracy and stability in every screwdriving operation but also allows the cobot to work safely alongside humans within the same workspace.

This represents an important step forward in the automation roadmap, helping businesses minimize manual errors, increase productivity, and maintain consistent product quality, even as production volumes grow or product variants change frequently.

The collaborative robot automatic screwdriving solution is suitable for a wide range of industries and offers the following outstanding features:

– High precision: Excellent quality control with accurate control of torque, position, and screw sequence, minimizing issues such as missing screws, misalignment, and thread stripping.

– Safety & workforce optimization: The cobot works safely alongside human operators, reducing heavy labor and repetitive tasks, allowing personnel to focus on higher value-added activities.

– Quick setup, easy operation: Simple and intuitive programming interface enables fast setup and straightforward operation.

– Increased productivity & consistency: Continuous operation with uniform screwdriving speed and precise tightening force, reducing errors and dependence on operator skill level.

The automated screwdriving cobot solution ensures stable and efficient operation across a wide range of industrial production conditions, and is particularly well-suited for the following industries:

– Electrical & electronics: Assembly of device housings, modules, and sub-assemblies on continuous production lines.

– Automotive & motorcycle: Assembly of frames, batteries, lights, and interior modules on moving assembly lines.

– Home appliances: Refrigerators, washing machines, air conditioners, ensuring consistent assembly quality.

Contact ETEK for more detailed consultation

Let ETEK partner with you from assessment – design – manufacturing – installation – technology transfer.

Address: 189 Phan Trong Tue Street, Thanh Liet Ward, Thanh Tri District, Hanoi, Vietnam

Hotline: 0965800166

Email: info@etek.com.vn

Website: https://etekautomation.com.vn

In the context of the mobile phone manufacturing industry increasingly requiring high speed and precision, the application of automation technology to the product quality inspection line is becoming an inevitable…

Our Painting Solution provides an automated system for applying consistent and high-quality coatings to various products, ensuring a smooth and uniform finish every time. This solution is ideal for industries…

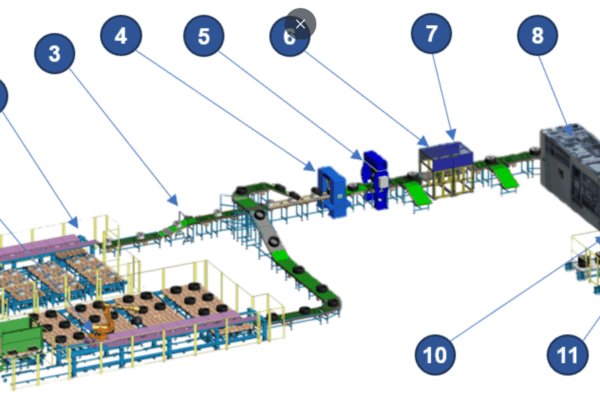

The automotive industry demands high-volume tire manufacturing solutions that deliver exceptional speed, consistency, and reliability. ETEK Automation provides comprehensive tire assembly line systems that integrate advanced automation technology to meet…

In the automotive manufacturing industry, the quality of the paint layer not only determines the aesthetic appeal but also directly affects the durability of the product. The application of painting…